8 Tips Of CNC Machining Titanium

The popularity of Titanium alloys as a material for structural and other parts is growing exponentially. Since, titanium holds an incredible strength to weight ratio and resistance to corrosion, it has become a winning component all across the industry verticals like aerospace, automotive, and medical. Consumer product designers, industrial engineers and architects appreciate its material properties like-

- Good machinability

- Ductility

- Surface treatment options

- Recyclability

Why choose CNC machine titanium?

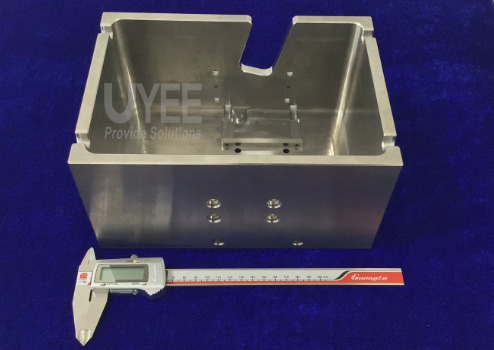

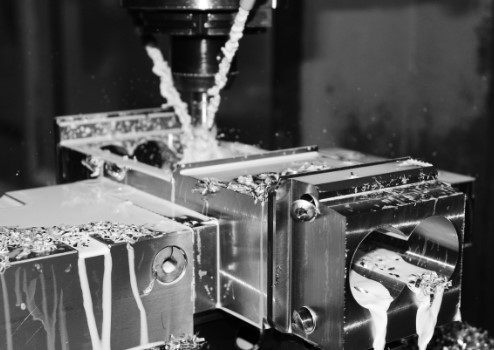

CNC machining titanium is always considered as one of the best manufacturing technique. It widely help industries in getting the most reasonable and exact titanium parts. It typically employs computerized controls and machine tools in order to eliminate the layers of material from a stock piece—commonly known as the blank or workpiece and produces a custom-designed part.

With custom titanium manufacturing, it helps you in expediting any production order in quantities. This process accepts the design and specification from the compatible software programs that contributes crucially in producing precise and consistent matched parts. One of the best part of CNC Machine Titanium is that it requires little maintenance services except cutting new implements occasionally.

You can connect with the best professionals for custom titanium manufacturing services who can work continuously to meet your demanding deadlines. Here some of these important tips of CNC Machining Titanium-

1. Keep Temperatures Down

Since Titanium is a bad conductor of heat, most of the energy is produced during the cutting process. Such heat often leads to harmful impacts that can result into impulsive failure in tool. It can weaken your tool and lead to rubbing that generates even more heat.

Based on the constituents that you are incorporating, this can also be a risk of fire. However note that when your tools become dull, it could be expensive enough for you and may damage your work.

Along with that, poor heat dissipation can cause strain hardening, where in the edges of your work piece becomes tough and then it becomes difficult to give a cut. Such a hardening effect will trouble the speed pace where the cutting process is conducted. Therefore, you can incorporate coolant that can control the temperature and gradually keeps it down.

2. Focus on making Your Surface Stable

Another effective way for adding strain on the tool is that you can bare it to the jarring and shock changes with a compulsion. Generally, this is quite an obvious thing to understand whenever it comes in and moves out of the material.

Now in order to make the surface stable, you will have to insert the tool directly inside the metal and then arc it privately to effortlessly penetrate the cut. Such an arc will not only accelerate the pressure but also makes the entrant less vibrating and help you slide into the same direction – anticlockwise or clockwise.

If you want that same result, consider a chamfer. A chamfer is a transitional or beveled edge used mainly to make a slanted surface. It contributes crucially in letting the tool to gradually penetrate instead of making any abruption. Such a tool helps you in easing the transition with limited application of force.

3. Take care of Your Tools

It is very much important to incorporate a sharp tool for an effective cutting. And in that case, Titanium wins the show very quickly. However, you will have to inspect or watch these tools frequently and replace quickly in case of wear and tear.

Any dull or ineffective tool will ultimately increase the proportion of heat and wear out even faster than you can think of. If you stuck anywhere, contact the professionals for CNC Machining Titanium for the best results.

4. Give some reasonable space to your tools

It is really quite imperative to give some space to your tools. For instance, if you are using a tool that has a smaller diameter, then it will help you in creating more exposure to coolant and air. This will permit the cut edge in spending reasonable time for cooling. Since it gives the metal time to breathe amidst the cut, it is called as an efficient technique for controlling the temperature.

5. Try to reduce Galling

Naturally, Titanium amalgamates with the other materials quickly that can lead to rewelding and galling of the edge during the process of cutting. However, if you keep the heat down with the help of such sharp tools and effective lubricant, you will be able to control the effect of galling.

6. Control Chipping

Edge chips happens when the metal pieces are cut, trodden and stick to the boundaries of the cutting tool. As more pieces build up on the cutting tool, this creates a negative impact on the performance. However, it can result into a more quickly damaged or a poorly cut tool. Therefore, it is advised to use a sharp tool and lubricant in order to reduce chipping.

-

Work holding

Titanium possesses the most desirable material properties and it acts more flexibly than other metals. Moreover, it requires a safe and secure grip on the Titanium work pieces and on the machine set up. So, the tip here is try to avoid the interrupted cuts and ensure that the tools works in a proper motion in contact with the work piece. Also, if you dwell into the drilled hole or hold the tool straight to a profiled wall, the tool will start running creating an excessive heat pressure. Further, it would result into hardening of the material.

-

Selecting a tool smaller than the pocket

Every tool requires clearance to allow for cooling. When mill a small pocket, the diameter of the tool must be less than 70% of the diameter of the pocket. If the clearance is less, the tool needs to be insulated from coolant and you will have to trap the chips to carry off the heat. In total, it helps in the creation of thick to thin chip.

What Can We Help You ?

Are you already thinking of availing Titanium milling service? We can definitely help you here. UYEE is a team of professionals who possess years of experience in delivering quality CNC machining services. To know more about what we do, get in touch with our experts at info@uyee-rapidprototype.com