Rapid Prototyping Services–Bring A CAD Model to Life

Rapid prototyping combines several technologies, such as CNC machining services, 3D Printing, and CAD modeling, to quickly build a scale model of a real item or assembly. Rapid prototyping techniques have been constantly refined and are now used in various industries, such as manufactured optic prototypes, automobile prototypes, and rapid injection molds.

Because of the various forming materials utilized, several types of rapid prototyping systems have diverse forming principles and system features. SLA, SLS, FDM, and LOM are examples of more mature processes.

What is rapid prototyping?

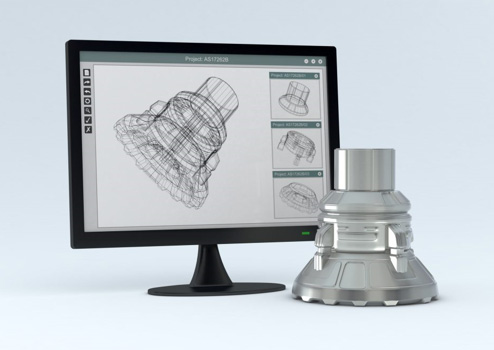

It is a prototype of an early physical model. You will then fine-tune this till you have the perfect final version. You are now ready to use or sell this as a product. So, the faster you create and perfect your prototypes, the sooner you can start selling them. All rapid prototypes start with a CAD design, but manufacturing hardware can include CNC machining, 3D Printing, and other methods.We can create prototypes out of any material that is compatible with your production gear. Procedures for surface finishing may or may not be provided. Rapid Prototyping services, as the name implies, emphasizes quick turnarounds. Because when it comes to developing and shipping a product, quicker is always better.

Application of CAD in Rapid Prototyping:

Rapid prototyping, commonly known as 3D Printing, is a type of additive manufacturing. The procedure begins with creating a virtual design using modeling or computer-aided design software. The data from the CAD model is read by a 3D printing machine, which then lays down layers of powder, liquid, or sheet material to create the real object from a sequence of cross-sections. Prototyping systems can typically generate 3D models in a matter of hours. But it also greatly depends on the size and capacity of machines, and the model what you built already.

Types of rapid prototype

Rapid prototyping is a technique and material that clients use in a variety of industries. It also includes various prototypes, such as visual-only prototypes and functional prototypes, to evaluate a part’s performance.

- Concept model: The earliest and simplest sort of prototype is a proof-of-concept prototype used to express the core idea of the part. Internal concept models are often retained and may go through multiple iterations.

- Display prototype: A display prototype (also known as a looks-like prototype) is a highly developed prototype emphasizing its cosmetic qualities. The prototype should be as close to the final element as possible, even though it may not function fully or at all.

- Functional prototype: It is designed to mimic the end-use part. It allows the designer to perform any mechanical testing required on the prototype to verify its function.

- Pre-production prototype: A pre-production prototype, also known as a factory sample, is the final prototype used before manufacturing. It is commonly used to validate the selected mass manufacturing process, guaranteeing that the manufactured part performs as planned.

Rapid Prototyping Advantages

Prototyping services can provide various benefits to engineers, industrial designers, and product development teams, including:

- They understand and execute concepts promptly and cost-effectively. Quick turnaround times and inexpensive pricing allow teams to go beyond simply illustrating a concept, making it simpler to comprehend the characteristics and design in the real world.

- Reiterate designs and include adjustments that allow for improved product evaluation and functional testing. This iterative approach provides a path for developing and improving the final product before releasing it to the public, ensuring that your design is optimized and error-free.

- The ability to physically demonstrate topics concisely and effectively

- Rapid prototyping transforms ideas, images, and concepts from a concept or two-dimensional visual into tangible goods that clients, colleagues, and collaborators can hold and witness in action.

- The capability of thoroughly testing and refining a notion. The ability to minimize design problems with a low-volume rapid prototype run aids in eliminating costly design errors that may not be apparent during an early assessment.

- By removing the requirement for setup and tooling, you can save time and money by choosing a rapid prototyping solution. In addition, because we may utilize the same equipment to create different prototypes with varying features and materials, we can keep total costs and turnaround time to a minimum.

Is Rapid Prototyping the same as 3D Printing?

When the technology initially became accessible, 3D Printing and rapid prototyping were so tightly linked that both names were interchangeable. Whether it was referred to as “3D printing,” “rapid prototyping,” or “RP,” everyone was talking about the same thing. However, 3D Printing has grown into end-use production capabilities, and the term “additive manufacturing” has been more widely used.

The earliest and most common use for 3D Printing is the rapid prototyping service. It utilizes 3D printers, which speed up the prototype, whether outsourced or in-house, by eliminating conventional devices or shipping bottlenecks. From proof of concept to actual prototypes, alliterations may be produced in 3D. The same 3D print technology used for the completed product is being utilized more and more to speed up prototyping.

What Is the Best Way to Begin Rapid Prototyping?

All you need is a 3D printer to get started with fast prototyping and additive manufacturing. There are, however, several options for getting there. A 3D printer may be purchased in a variety of sizes, from desktops to large-format 3D printers. With us, you may receive your part in three simple steps: You provide your CAD file, we provide you an estimate, and then our 3D printing professionals do the rest.

Conclusion

Rapid prototype services are used to improve and speed up engineering. By speeding up your workflows and eliminating bottlenecks and other pain points associated with typically drawn-out prototype cycles, you may create a new product with a shorter time to market. In addition, rapid prototyping that is better-tested and less expensive is a win for your engineering team.