The features and performances that make titanium an out-of-the-box material are also the ones that make it difficult to machine. Unfortunately, titanium imposes complex CNC machining requirements. Combining a well-planned process with specialized application expertise and titanium-optimized setups may improve it to take advantage of titanium’s outstanding characteristics for desired results.

While machining titanium, you need to follow some rules and regulations in order to improve better the productive and effective. Utilize the following nine professional guidelines for titanium CNC machining process and related alloys. You will get the desired outcome and experience from titanium machining according to the below guidelines:

1. MAINTAIN A LOW RADIAL ENGAGEMENT

One of titanium’s most significant problems is heat dissipation. Compared to other metals, a greater proportion of the heat generated during the titanium machining process is transferred to the tool. Due to this phenomenon, the radial engagement determines the surface speed of this metal.obviously it will impact on the manufacturing process.

Full slotting—that is, engagement in all directions—requires a very slow surface speed. However, by decreasing the radial contact, the cutting edge produces less heat and has more time to cool before penetrating the material on the next revolution.It is the base experiences for a professional titanium machine shop.Thus, it may raise the surface speed by reducing radial engagement while preserving the cut point temperature.

2. INCREASE THE NUMBER OF FLUTES

End mills with four or six flutes are often utilized. It may be too little titanium. Ten or more flutes may be more effective.It mainly depends on the dimensions of the part .Increased flute count compensates for the low feed per tooth requirement. The tiny chip produced as a consequence of this allows for a high-flute-count end mill to improve productivity.

3. CONSTRUCT A THICK-TO-THIN CHIP

This concept is often referred to as “climb milling.” known as “conventional milling,” this kind of machining results in a thin chip and gradually becomes thicker. A tiny chip is incapable of absorbing and ejecting the produced heat absorbed by the cutting tool, it is in particular that need to pay attention during milling .Then, at the chip’s departure point, higher cutting pressure creates a risk of chip adhesion.

Climb milling—or the creation of thick-to-thin chips—begins with the cutting edge cutting through the surplus material and emerging on the completed surface. Contour surface milling requires meticulous inspection of the tool path to verify that it continues to enter the surplus material and leave it on the completed surface in this manner.

4. ARC

Tool life is lost in CNC manufacturing titanium parts and other metals during jarring changes in force. The most dangerous of these times often come when the instrument makes contact with the substance. Direct feed into the stock provides a comparable effect to hammering the cutting edge.

Instead, glide in gently. To do this,the goal is to build a tool path that enters the material in an arc rather than a straight line. The toolpath arc should be moving in the same direction as the tool rotation during milling operations. The arcing entrance route enables a progressive rise in cutting power, avoiding tool grabbing or instability,make sure that the process runs smoothly.

5. CONCLUDE WITH A CHAMFER

Additionally, abrupt variations in force may happen at the tool’s departure. The sudden shift in the direction results in an equally abrupt change in force, startling the tool and probably it will be marring the component’s surface.

6. MAKE SECONDARY RELIEF A PRIORITY

While a sharp cutting edge reduces cutting forces in CNC titanium parts, it must also be robust enough to withstand cutting pressure. A secondary-relief tool design is capable of accomplishing both of these objectives. The initial positive region of the cutting edge resists pressure and then falls away to improve clearance.This is a good step. Secondary relief is a typical feature of cutter tooling. However, with titanium, in particular, testing with various secondary relief designs may reveal unexpected differences in cutting performance or tool life.

7. MODIFICATION OF THE AXIAL DEPTH

Oxidation and chemical reactions may affect the tool depending on the depth of cut while machining some of deep structure part.. When making repeated axial cuts, this damaged region of the tool may result in work hardening and undesirable surface lines on the part, necessitating an early tool replacement. To avoid this, protect the tool by varying the axial depth of cut between passes, spreading the problematic region along with the flute. In turn, by paralleling the next pass instead of depth-of-cut notching, a similar result may be achieved.

8. SELECT A TOOL THAT IS MUCH SMALLER THAN THE POCKET

Since the machining tool absorbs heat easily in titanium parts manufacturing, make sure it has enough space for cooling. When milling a tiny pocket, the tool’s diameter should not exceed 70% of the pocket’s diameter,this is significant. Fewer clearance risks effectively isolating the tool from the coolant and trapping the chips that normally conduct part of the heat away.

The 70% rule also applies to a tool milling over the top surface of a work piece. In this instance, the feature’s width should be 70% of the tool’s diameter according to the experience of past years. It will speed the process up hugely .The tool is angled by 10% to promote the production of thick-to-thin chips.

9. INSPIRE YOUR WORK USING TOOL STEEL

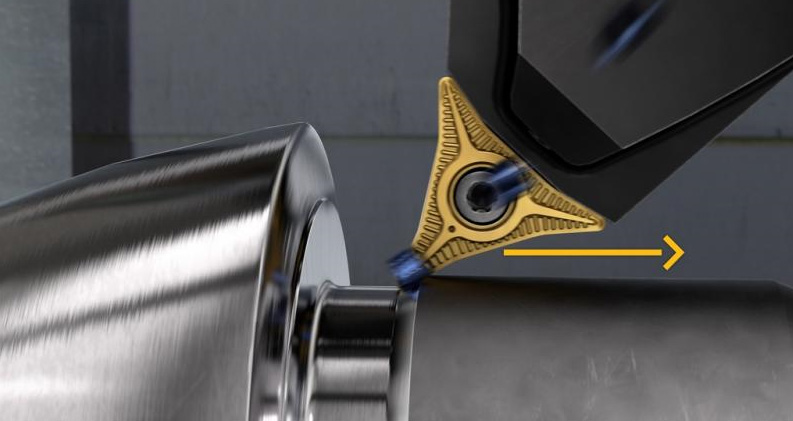

Machining tool steels in the mold sector are not the only use for these types of feed mills. A high-feed mill needs a shallow axial depth of cut,however, the tool allows for greater feed rates than milling cutters with more traditional design solution when operated at this shallow depth.

A cutting-edge insert with a large radius curve is essential for a high-feed mill. This radius distributes the chip development across a substantial contact area on edge. In titanium milling process, the tiny chip compensates for the metal’s low feed per tooth. The chip’s thinness enables a greater preset feed rate than would be feasible otherwise.

SUMMARY

We hope these machining tips and tricks will help you machine titanium in the best possible way. Reach out to us for matchless CNC machining technology and expertise. If you are looking for titanium machining services, then reach out to us right away! We have a professional engineering team who specialized in manufacturing titanium part. We would love to hear from you!