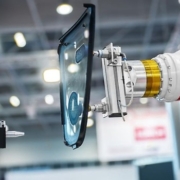

How to Offer the Best CNC Machining Services for Customers?

You are able to find out a lot of machining shops through by searching on the Google. Bing. Yahoo. They are from many nations and serving all kinds of industries accordingly .Almost these manufacturers could provide CNC prototyping services and a series of volume production. However, as a professional and excellent machined supplier, how to offer the best CNC machining services for your customers?

Response Fast to Customers Questions and Quote

The sales should reply quickly after received the RFQs from the customers, for some of uncertain issues, sales should discuss with the engineering team to get a confirmation before answering, especially on the design issues. In fact, most of the machining customers are designers, they like to communicate with the manufacturer to discuss their ideas and designs in order to optimize the design better. Even you can also provide some suggestions or solutions to help customers save cost.

Choosing the Correct Materials According to Customers Requirements

After received the order from customers, the first step is prepared for original material ordering .You have to provide the correct materials, if customers require Aluminum 7075, then, you cannot provide Aluminum 6061 instead. And also, for some of material colors difference, you need to pay attention too, for example, there are both white and black POM. You have to confirm with customer which one they prefer .

Checking the CAD Models before Making CNC Programming

In China , engineering people like to work with PROE or UG software ,but most of western designers and engineers like to use SolidWorks as their working software ,when converting 3D files ,maybe some issues will be happening ,such as : perhaps some of caves will be incorrect or broken. Thus, programming maker should repair it before starting programming job.

Checking the Programming before Inputting the Machines

After the programming done, it should be checked by the leader or another coworker before inputting the machines to make sure it correctly. If you have not checked it ,once the machine running , the work piece will be incorrect if some of programming made a mistake .So this step is very important for the whole CNC machining process .

Parts need to be Inspected and Checked after Machined

In fact , the machinist should pay attention to the work piece during machining step , and observe if it is running according to the programming of setting up ahead .Especially for some of stiff metal cutting. Such as, it probably produce huge noise and smoke during titanium machining process. These factors the machinist should know. After machined parts done, you need to check and inspect them before starting deburring, polishing, anodizing or other finishing. Such as: if customers request threading? Or some tight holes? The clearance of sharp corners? It will cost too much if you did not inspect after machined, and directly make the process of finishing, when you looking back to make an inspection on the parts. The operators should check the drilling tools with Caliper before drilling holes to keep the tools what they use are 100% correct, rather than feeling with their experiences.

Make the Final Inspection before Parts Packing

You need to check and inspect the quantities, dimensions, tolerances, threads, and some finishing again before packing the parts .QC should be responsible for the whole quality control process. And make a full inspection on each part. For some of customers who are demanding the report of quality inspection. QC will be prepared for it. In the meantime, if customer has emphasized the fitting relationship between some of parts, then, the manual workers must try to fit them.

Keep the CNC Programming Well for Future Production

In machining industry, usually customers will make one CNC prototype or a few pieces as test and checking. Once the prototype approved, then, the next step is production running .So the manufacturer has to keep the programming,if the customer modified their design ,programming makers can also adjust and remake it accordingly on the former programming, thus ,it can save lots of time .