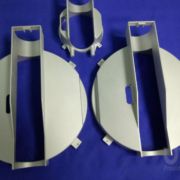

Assembly CNC Aluminum Prototype Parts

When we make an assembly with parts, each part ends up being an important piece in the total function of the machinery. If for some reason, one of the parts fails, it could end up having a massive failure, which would end up generating large losses for any company. For this reason, maximum precision in the elaboration of own assembly parts is of utmost importance, much more so if it is prototype parts: the part must be elaborated with the utmost precision and without margin of error.

Why use Aluminum?

In the Assembly CNC aluminum prototype parts creation industry there is a specific reason why the use of this metal is paramount. First of all, it should be noted that the most used material is its own aluminum alloys. The elements of these soft alloys tend to be extremely malleable and it is also added that they are recyclable. In this way a large amount of energy is conserved and subsequent damage to the environment is avoided.

In addition to this, aluminum has the property of joining other elements such as: magnesium, copper, zinc and silicon. By adding heat to the formula, they end up creating quite resistant alloys, which allow to have a great overload, without deforming. This fact is extremely important in the industry, since the slightest deformation can lead to massive damage to machines that can cost thousands of dollars. The fact of creating parts so resistant to pressure and rupture, allows the risk of damage to be minimal, if properly maintained.

And also,aluminum can be anodized with all kinds of colors ,when fitting some components up ,people not only want to test and check the function of the whole device , but also want to get the better visual experience and enjoyment,so with colorful components to fit up together , it will be easier to get this achivement . That’s why aluminum is quite welcomed and boomed in all kinds of industry.

Is the CNC viable for prototyping?

Most different industries are viewing 3D printing as a force that directly dominates the rapid prototyping market. But given this, CNC machining also becomes an important process when manufacturing aluminum prototype parts. This process allows us to understand the reason for the product, the forms that the prototype can take and finally allows the reasoning of the reason for being of these prototypes. CNC machined prototypes can perform many different functions with comparing to 3D printing way .

Machining could become an excellent manufacturing option when creating prototype parts, but for this we must take into account the different natures that a prototype can present. What will the device be used for? What material will it be made of? What material will be applied to the last part? If the user clearly investigates everything necessary, he ends up having much more acceptable prototypes.Sometime ,for some of rare metals ,machining is the only option to produce the relative parts .

UYEE as a solution for the inspection and verification of Aluminum Prototype

Focus On Details:

The verification of the originality of the parts can be taken as one of the most important processes in all work related to machinery. The duty of the company is to provide the facility for the inspection of the characteristics of the piece, so that it cannot generate any failure. Width, size, and tolerances of each part should be checked and inspected.

Responsibility:

UYEE acts as a great solution by providing the necessary instructions and guidance so that a customer can not only “order a part”, but on the contrary, can order exactly the whole assembly product that they need. This is achieved through a standard inspection based on 3D data that the customer can obtain on their machinery and ultimately directly affects the creation of the part.

What We Can Help You ?

Finally, an expert capable of analyzing the CAD data is needed to perform the cutting and modeling of the aluminum. If you look for a reputable company, you end up having parts of the metal with impressive speed, while maintaining strict standards at the same time. All this procedure does not carry with it only theory, but a large amount of experience in dealing with the aluminum milling that will be used: depending on the part needed, different alloys can be used, or different forms that will end up carrying out the necessary task without creating failures. That is why UYEE ends up being one of the best solutions. Being a highly renowned company, it combines knowledge with experience, and with it, your interests are protected.