Helping A Designer To Solve A Problem With CNC Plastic Machining

Material: Nylon with 30% glass fiber

Process: CNC Machining

Finished: Sanded,Painted

Dimension: As clients’ requirements

Tolerance: 0.05-0.1mm can be customize

Description As Following:

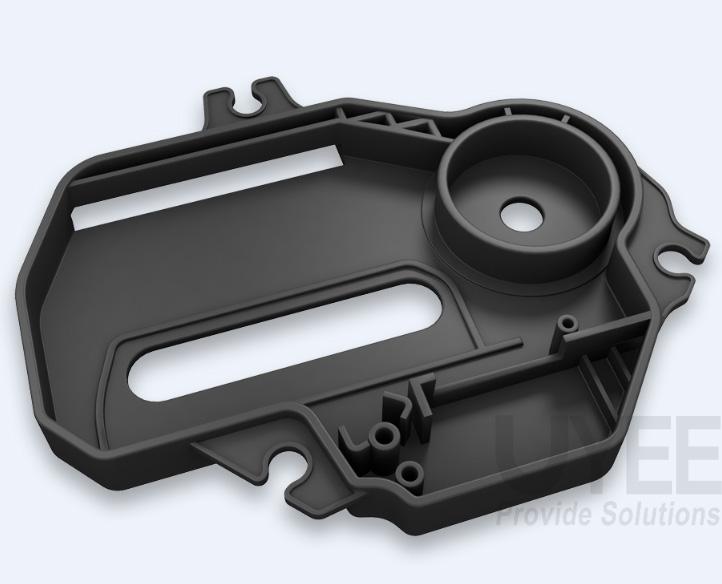

This Prototype is made out of Nylon+GF30% by CNC plastic machining ,for one of our clients who is from USA.In the beginning ,He made the prototype locally in 3D printing technology after completed the final design in order to see the result quickly and early .All dimensions and structures were Okay,but the material features and surface finished can not meet the test ,the surface finished was quite rough ,So he contacted with us ,and asked if we are able to provide an option,making this prototype with a nice finishing, and a plastic with more better heating resistance and mechanical strength,in the mean time, be able to save the production cost .We recommended the material Nylon+GF30% after analyzed the product application.

Making CNC Prototype is totally different from 3D printing method , during machining process ,some of sharp corners can not be clearance in certain joint section of the right angles because of cutting tool .But 3D printing prototype can be a good performance on this .So We communicated with the client which sharp corners have the assembling requirements that have to remain.After machined ,according to the client’s request ,our technician cleaned up by manual work on the round corners to be sharp corners for the key assembling area,and sanded the surface to be smooth,then painted in order to achieve a nice looking finished.The client was very happy after got it ,all positions were fitted so well .and also ,the material Nylon+GF30% is able to meet all his test result .