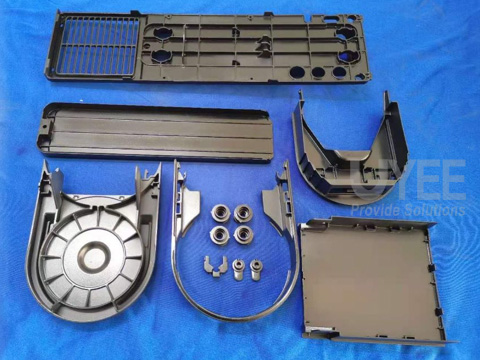

Description As Following:

At the side of left showing is the inner ,here what you see is the external ,very smooth and phenomenal finish ,because after machined , in order to get a better parallelism, flatness, the piece needs to grind again and again. In the beginning ,the roughness what customer required is 0.1 ,equivalents to the mirror result ,however ,it is impossible for titanium ,ultimately they can accept 0.8 after we communicated with them ,so now what you see is 0.8 roughness in the picture showing .

Machining titanium is not an easy job ,expecially with such high requirements for finishing and tolerances ,however ,what we did has exceed the client’s expectation ,thanks to our engineering team’s skills and vast experiences in industry ,and be cautious to each details .If you have titanium machined prototype or low volume production parts to be manufactured ,please contact us ,provide the CAD model in IGS or STP format with the PDF drawing if you have some high requirements ,such as : tight tolerance,threads ,flatness …ect .Take a look at our machining service suitable for both very small detailed or larger complicated titanium parts .We are competent !

| Material | Titanium grade 5 |

| Process | CNC Machining |

| Dimension(Unit: MM) | 351*152*73 |

| Tolerance(Unit: MM) | ±0.05 |

| Application | Defense |

| Finished | Remove all sharp and burr, grind |

| Delivery Time | 15 Days |

| Supply Ability | 100 Pieces – 200 Pieces/Month |