Titanium Anodizing: Your Comprehensive Guide

Titanium is an attractive metal renowned for its durability, resistance to corrosion, and biocompatibility. Titanium anodizing is a versatile and frequently employed surface treatment process that enhances titanium’s properties. This comprehensive guide will give you a thorough understanding of titanium anodizing, including its process, applications, benefits, and risks.

What is Titanium Anodizing?

Titanium anodizing is an electrochemical procedure that transforms the titanium’s outer layer into a lustrous, durable, corrosion-resistant oxide coating. In this process, titanium is immersed in an electrolytic solution and exposed to an electric current. The final result is an anodic oxide layer that may be customized for various uses.

Historical Background

The durability, corrosion resistance, and biocompatibility of titanium make it a desirable metal. Titanium anodizing is a flexible, standard surface treatment method that improves titanium characteristics. You will obtain a detailed grasp of titanium anodizing, including its method, uses, advantages, and hazards, via this in-depth manual.

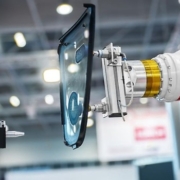

The Titanium Anodizing Process

Titanium anodizing is a multi-step procedure involving pre-anodizing prep, actual anodizing, and finishing.

Pre-Anodizing Preparation

- Cleaning: The titanium substrate is thoroughly cleaned to remove contaminants, grease, or oxides. This step is essential to ensure the anodizing process proceeds smoothly.

- Etching: After cleaning, the titanium may be etched to create a microscopically rough surface, which promotes adhesion and oxide formation during anodizing.

- Deoxidizing: Deoxidizing removes any remaining oxides. This step is crucial for uniform anodic oxide formation.

Anodizing Process Steps

- Immersion: The prepared titanium is immersed in an electrolyte bath, usually containing sulfuric acid or other proprietary solutions.

- Electric Current Application: A direct current is applied between the titanium workpiece (the anode) and a lead cathode, forming an anodic oxide layer on the titanium’s surface.

- Controlled Oxide Formation: The thickness and properties of the oxide layer can be controlled by adjusting the process parameters, including voltage, current, and bath composition.

- Colouring (Optional): For decorative or labelling purposes, colour can be introduced by immersing the anodized titanium in a dye bath.

Post-Anodizing Finishing

- Sealing: After anodizing, the oxide layer may be sealed by boiling the titanium in deionized water, which enhances corrosion resistance.

- Quality Control: The anodized titanium is inspected for uniformity, colour consistency (if applicable), and other desired properties.

Types of Titanium Anodizing

There are three main types of titanium anodizing, each with distinct purposes and characteristics:

Type I: Commercial Anodizing

Type I anodizing creates a thin oxide layer on the titanium surface. It is primarily used for essential corrosion protection, as it doesn’t significantly alter the metal’s appearance. It is commonly used in the aerospace industry to reduce titanium’s reactivity.

Type II: Decorative Anodizing

Type II anodizing enhances the aesthetic qualities of titanium. It results in a thicker oxide layer, which can be dyed to achieve various colours. This type is often used in jewellery, architectural components, and consumer goods.

Type III: Hard Anodizing

Type III anodizing is employed when extreme wear and corrosion resistance is required. This process produces a thicker and more durable oxide layer. It is commonly utilized in industrial and military applications where durability is paramount.

Applications of Titanium Anodizing

Titanium anodizing has various applications across various industries due to its unique properties and versatility.

Aerospace Industry

In the aerospace industry, Type I anodizing reduces titanium’s reactivity, preventing it from reacting with fuel and other chemicals. Type III anodizing is employed to provide wear resistance and protect critical components.

Medical Implants

Titanium is the perfect material for medical implants due to its biocompatibility and resistance to corrosion. The implant’s surface is further improved by anodizing, increasing its biocompatibility and corrosion resistance.

Sporting Equipment

Titanium anodizing is commonly used to produce sporting equipment like bicycle frames, golf club heads, and tennis rackets. The process enhances the material’s durability and aesthetics.

Jewellery

Jewellers often use decorative anodizing to colour titanium rings, pendants, and other pieces, creating unique and vibrant designs.

Architectural Components

Anodized titanium is used for exterior cladding, roofing, and decorative elements in architectural design. The oxide layer’s durability and colour options allow for visually striking and long-lasting architectural solutions.

Benefits of Titanium Anodizing

Titanium anodizing is a popular option across many sectors since it is a surface treatment method with many advantages. The following are some of the main benefits of anodizing titanium:

- Increased Corrosion Resistance: Titanium is anodized to provide a thick, firmly adhering oxide coating. The metal’s resistance to corrosion is significantly increased by this layer, which serves as a protective barrier. As a result, anodized titanium parts are perfect for usage in challenging settings like those in the aerospace and maritime sectors.

- Increased Wear Resistance: Hard anodizing produces a thick, robust oxide layer. Anodized titanium components are excellent for lifespan and durability because of the layer’s significant improvement in the material’s resistance to wear and abrasion. In industrial settings and military applications, this gain is particularly significant.

- Aesthetic Choices: Titanium surfaces may be decorated with various hues and patterns thanks to decorative anodizing. This makes anodized titanium a fantastic option for sectors like jewellery and architectural components where aesthetics are crucial. The ability to alter the metal’s look gives the completed items a distinctive and eye-catching dimension.

- Biocompatibility: Titanium is a popular material for medical implants due to its biocompatibility. The oxide layer added during anodization increases titanium’s biocompatibility even further. In medical applications, this is crucial since it guarantees that implants are secure, unresponsive, and well-tolerated by the body.

- Electrical Insulation: Titanium that has been anodized also offers excellent electrical insulating qualities. This is especially useful for applications like aeronautical parts or medical implants where electrical conductivity is desired. The anodic oxide layer adequately shields the titanium underneath from electrical currents.

Considerations in Titanium Anodizing

Material Selection

Material selection is essential since not all titanium alloys can be anodized. The outcome and functionality of the anodized layer might be affected by the composition and purity of the titanium alloy.

Design Considerations

The component should be designed to accommodate the anodizing process, including masking any sections that shouldn’t be anodized and any potential dimensional changes.

Environmental Impact

The process of anodizing often uses chemicals and produces trash. Following correct disposal methods and considering more ecologically friendly options is crucial to reduce the environmental effect.

Conclusion

Titanium anodizing is a flexible and vital procedure that improves titanium’s characteristics for various uses. Improved corrosion resistance, wear resistance, and aesthetic alternatives are provided by anodized titanium, whether used in the aerospace sector, medical area, sports equipment, or jewellery creation. Titanium anodizing will continue to be a crucial tool in industries’ toolboxes as they develop and discover new uses for this extraordinary metal, enhancing the performance and lifetime of their products.