Heat Sink Development-What You Need To Know

The heat sink is modest, yet it heats the electronic components that power the magic device. For example, if the computer is heated for an extended period, the heat sink in the CPU can serve as a cooling device, allowing the computer to work longer. The power supply usually is not heavy in the TV set.

How Does It Work?

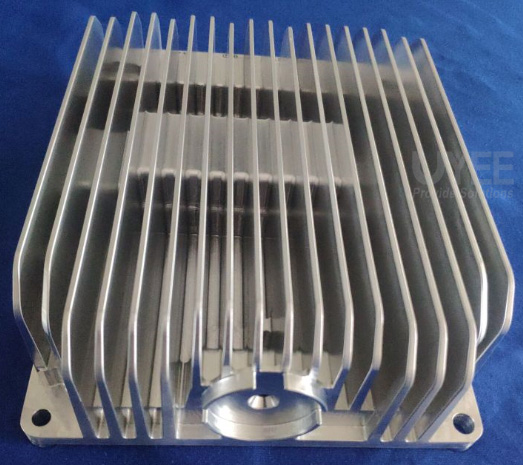

For Heat sinks, there is a wide range of materials available. Such as: aluminum, brass, SUS .However, different materials have significant impact factors on the heat sink’s heat dissipation effect.Although silver is the best material for heat conductivity testing, it is not the first option because of its high cost. Copper is the second most thermally conductive material, with about twice the thermal conductivity of aluminum. However, aluminum is the most widely used. Aluminum is the most versatile material, regardless of price or heat transfer. Aluminum is a lightweight and economical metal.

What Is the Function of the Aluminum Heat Sink?

The heat sink functions on a fairly simple concept. The surface area is enlarged relatively. As a result, the heat sink must meet several requirements, including rapid heat absorption, rapid heat dissipation, and efficient heat transfer.

Common Manufacturing Ways for Aluminum Heat Sink

Extrusion of Aluminum heat sink

Extrusion is a good technology for mass manufacturing aluminum heat sinks since it requires little investment, has a fast development cycle, and cheap production costs. Aluminum 6063, a typical extrusion material with high heat conductivity, is a popular choice. The heat sink embryo is created by melting an aluminum 520-540°C under high pressure and then allowing the liquid aluminum to flow through grooves in an extrusion mold.

The heat sink fin is then used to produce the profile groove, heat sink embryo, and several other procedures. Completing this therapy, on the other hand, comes with several drawbacks. The Fin is first made using an aluminum extrusion method.

Fin thickness and length ratio are restricted to a specified range, as is the pin-fin ratio. It is one of the primary testing standards for aluminum extrusion technology. The greater the PIN-FIN ratio, the greater the heat sink’s effective cooling surface. Aluminum extrusion is mostly utilized in heat sink processing to create lamellar fins or columnar fins.

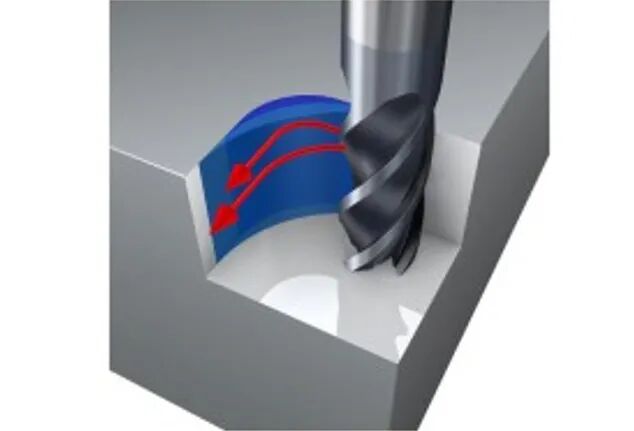

Machined Aluminum heat sink

Turning, drilling, milling, and grinding are some of the machining techniques used on CNC Aluminum machining . Based on the structure of the components, this approach may be applied in several ways, including the use of most mechanical parts such as heat sink grooving, plate forming, and bottom surface treatment, among others. The drawback is that tool wear would be quick, and human participation in machine management would be labor-intensive.

Aluminum heat sink – Die casting

A popular cutting process is to dissolve aluminum alloy raw material into liquid at high pressure and then quickly fill the liquid material to CNC. According to the model, a die casting process began to work after refreshment and further treatment, and the once die casting was formed into a heat sink. As a result, we can use the procedure to create a thin, dense, or complex fin. This method, however, has a flaw in that it affects heat conduction and the mechanical properties of the material. As a result, nuclear thermal conductivity can’t have it both ways.

Who Uses Aluminum Heat Sinks?

Premier Engineered Products manufactures die-cast heat sinks for a diverse spectrum of global companies. Some of the important industries we service and know a lot about are as follows:

- Testing and custom machine manufacturers who create their customized computers and casings

- Wide-park enterprises require sophisticated sound and auditory systems to deliver staff updates, information, and alarms across large geographic areas.

- Industrial mechanics, makers of automotive trucks and equipment, and service providers for logistics, agricultural, and other industrial, automotive brands

- Telecommunications firms, ranging from business to business internet providers to individual cellular service providers.

- Any firm or situation that can benefit from the ability of an aluminum die-cast heat sink to safeguard even the most sensitive equipment.

What are some common aluminum heat sink surface finish options?

Sandblasting

By forcefully hitting the surface of the workpiece under high pressure, sandblasting may successfully remove some debris or knife lines on the surface of CNC aluminum machined parts. It may also enhance the mechanical properties and fatigue resistance of the aluminum heat sink surface and make the components seem more uniform and gleaming.

Brushed

Brushed surface treatment can give the items a more metallic sheen and a more trendy appearance.In addition to its ornamental function, drawing can extend the heating surface of parts to a certain level, promoting the usage efficiency of the Aluminum heat sink.

Anodized

Today, Anodized is one of the most popular surface treatment processes for aluminum heat sinks. The surface of the parts will form a layer of protective film through by using anodizing process, that could protect the parts from scratching, and loss and overcome the surface area hardness of aluminum alloy faults. Diverse advantages presents out .

Electroplating

It is a good way to protect and decorate an aluminum heat sink to be a good looking finished. The principle is similar to that of anodized aluminum. It is also a protective film layer on the surface of the parts to avoid anodization of the surface of the parts. It improves the components’ reflection, wear resistance, electrical conductivity, and corrosion resistance all at the same time.

Conclusion :

We have substantial knowledge in heat sink product design methodology. We can help you with your custom design and customization needs. Please send us your 3D files or drawings for a quotation if you have any new project requirements, or call us if you have any questions. We are a technical sales staff that pays close attention to every point of communication and interface with you to ensure that there are no surprises for your positive customer experiences.

Knife handle

Knife handle Damping milling cutter

Damping milling cutter Cutting parameters and tool path programming

Cutting parameters and tool path programming CNC machine

CNC machine

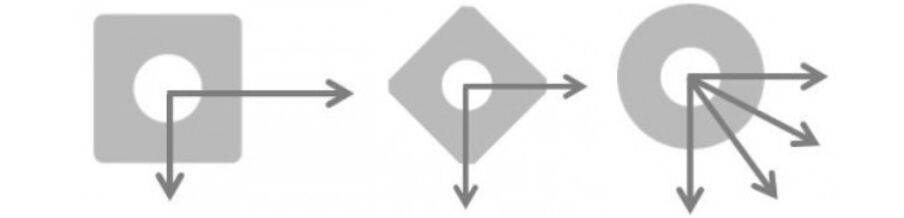

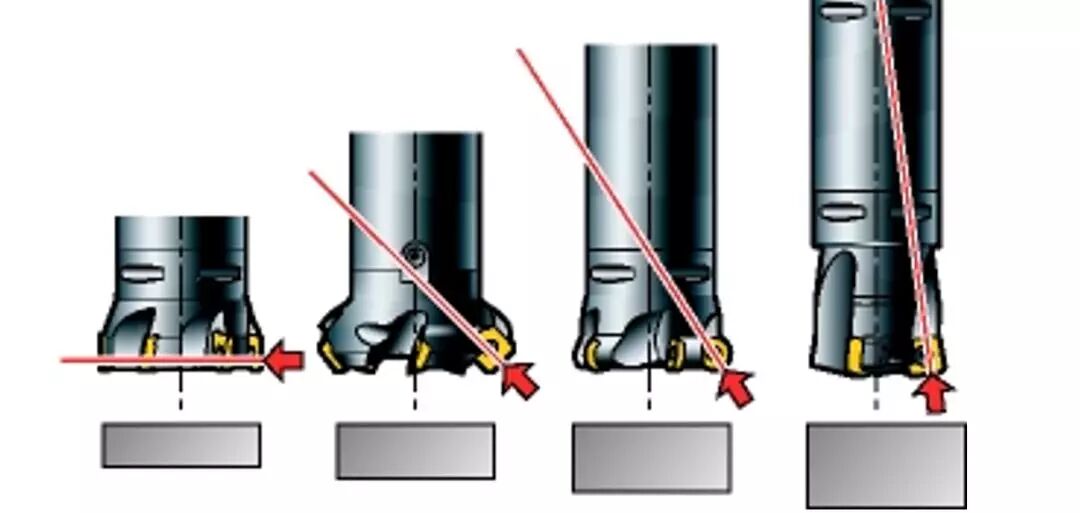

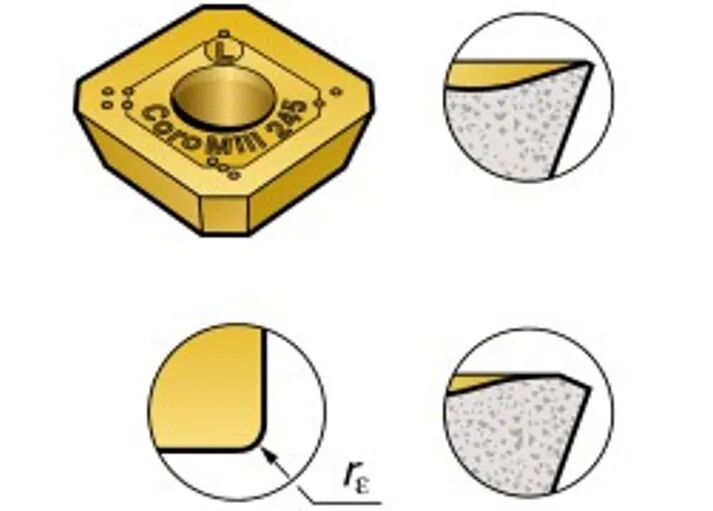

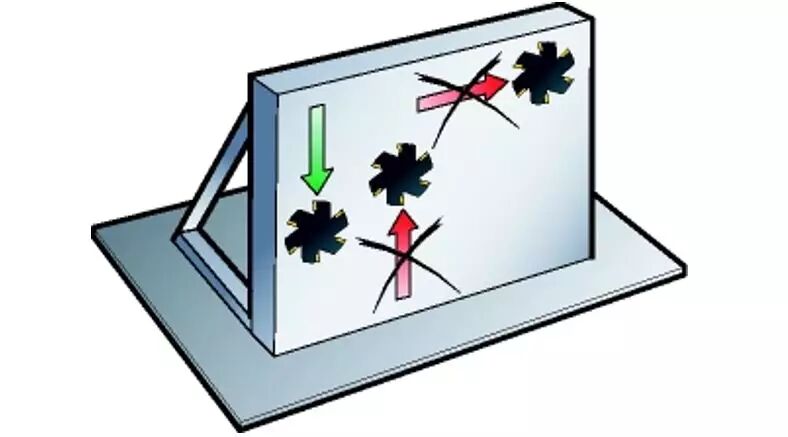

Plain milling is sometimes get referred to as surface milling. It employs a horizontal mill, which means that the cutting tool’s rotational axis is parallel to the cutting surface.

Plain milling is sometimes get referred to as surface milling. It employs a horizontal mill, which means that the cutting tool’s rotational axis is parallel to the cutting surface.