5G Is Changing Our Life

We have been hearing about it for years, both because of the technological revolution that it entails and because of the typical fears that it arouses among those who do not understand it. But after several years in which it seemed that it was not going to arrive, it seems that prototype manufacturing for 5G facilities will definitely begin to take its first steps in 2019, and both operators and mobile manufacturers (Samsung, Huawei, Xiaomi or LG, among others) are doing your first announcements related to your implantation. But there are still those who do not quite understand what all this for 5G facilities is, not even some presidents of great powers, so we are going to explain what about 5G.

What is 5G?

The idea behind this development is to allow you to make a phone call, write as before, and above all, surf the Internet at a much higher speed than the current one. Do you remember how the speed you had a few years ago on your home Wi-Fi was much slower than it is now? Well, this is similar. In fact, since you are making use of your memory, you may still realize how much your connection improved when you began to change the 3G connectivity of your mobile to take advantage of 4G, you started to be able to navigate at much more powerful speeds that allow you see current websites without problems, as this is a new evolutionary leap.

This fifth generation of wireless communications is the one that is going to try to make viewing a website on a mobile phone like opening any other file, with a speed so fast that we should be able to load Ultra HD videos or 3D models almost without blinking. The official standard has already been approved, and it promises to be between 10 and 20 times faster than current mobile connections.

The Development of 5G

The standard exists, the first mobiles to support it have already been presented, and operators such as Vodafone have already announced that they will begin to deploy it. But currently you can’t use it yet, so it remains to be seen if those speed predictions really come true from the start or if they still take a while to arrive.

What we are sure of is that on paper, prototype manufacturing for 5G facilities are an almost essential process to survive the electromagnetic bottleneck that exists in large urban agglomerations today. With more and more connected devices, it is necessary to increase capacity and allow even more to connect to, for example, support an always-connected ecosystem of smart cars or the increasingly developed Internet of Things.

What differences does it have with 4G?

In this table you will see the main differences between 4G, 4G + or LTE, and 5G. The speed will be much faster, so you can download content almost without realizing it. But even more important is the decrease in latency. Latency is the time it takes to transfer a data packet within the network, the time it takes for an action to arrive from the moment you perform it until it is consumed. Currently there are already very low latencies, but 5G facilities promises to lower them to between 1 and 2 milliseconds. Added to the download speeds, this will mean that if you click on a photo that you have in the cloud, it would take the same time to open it on your mobile as if you already had it in its memory.

In any case, and as we have said before, 5G facilities has not yet been implemented. This means that we can theorize or comment on what benefits it can bring, but that we will not definitely know until it is definitely implemented and it begins to be exploited. At the moment we have already seen demonstrations such as tele-assisted surgeries in real time, in which the surgeon performs the interventions from miles away. A good summary of what the jump from 4G to 5G means was given to us a few months ago by the chipmaker Qualcomm. For them, 4G served to connect people between them, and 5G facilities are a new leap that will allow “connecting people with everything that surrounds us”, promoting not only communications, but other sectors such as automotive, medicine, health or households.

How Can We Help on Your 5G Project ?

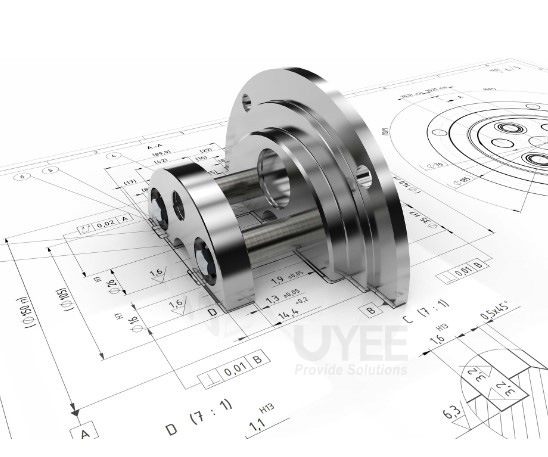

UYEE can provide rapid prototyping,CNC machining services to help you to custom prototypes for 5G facilities during the stage of new product development. If you have any questions or new projects for a quote, please don’t hesitate to contact us.

Adecco has carried out a study to measure the direct and indirect impact of artificial intelligence in the world of work. The result reflects that, despite the fact that this technology is still in full development, 37% of the human resources directors surveyed believe that artificial intelligence and CNC machining already have a significant relevance, is the present and is a reality at the moment. 48% maintain that the true impact will come soon, in the short-term future, and that you have to be prepared for when that happens.

Adecco has carried out a study to measure the direct and indirect impact of artificial intelligence in the world of work. The result reflects that, despite the fact that this technology is still in full development, 37% of the human resources directors surveyed believe that artificial intelligence and CNC machining already have a significant relevance, is the present and is a reality at the moment. 48% maintain that the true impact will come soon, in the short-term future, and that you have to be prepared for when that happens.

Be that as it may, the CNC Prototype already has a place in the hearts of manufacturers, and also in all customers who only want to see their dream of marketing their products come true, and that they reach the hands of all. When talking about prototypes, we make it clear that it is an initial idea that was materialized, this due to the obvious need that all creators have to observe and evaluate the behavior of a piece, long before it is present in the production lines.

Be that as it may, the CNC Prototype already has a place in the hearts of manufacturers, and also in all customers who only want to see their dream of marketing their products come true, and that they reach the hands of all. When talking about prototypes, we make it clear that it is an initial idea that was materialized, this due to the obvious need that all creators have to observe and evaluate the behavior of a piece, long before it is present in the production lines.

The designer Jessica has made this technique even more advanced, inserting buttons, expertly modeled on the triangles, making the clothes even easier to put on and take off. The result is amazing, as her dress moves adhering perfectly and flowing just like it was made of fabric. Thanks to the 3D scans of the model’s body she managed to get a perfect fit. She worked with a prototype manufacturer to optimize the print quality and aesthetics, thanks to the attention to every detail her garment was recently acquired by the Museum of Modern Art.

The designer Jessica has made this technique even more advanced, inserting buttons, expertly modeled on the triangles, making the clothes even easier to put on and take off. The result is amazing, as her dress moves adhering perfectly and flowing just like it was made of fabric. Thanks to the 3D scans of the model’s body she managed to get a perfect fit. She worked with a prototype manufacturer to optimize the print quality and aesthetics, thanks to the attention to every detail her garment was recently acquired by the Museum of Modern Art. and Under Armor, in the new technological concept, capable of combining 3D printing and shoes. Each of these multinationals has proposed a prototype of a shoe with a plastic sole made entirely with 3D printing techniques, and the future holds many other innovations.The application of rapid prototyping logic to the world of footwear seems to be an ideal solution for the most common problems .The first thing that comes to think of a shoe is the first fundamental advantage: the size. Surely many of us will have found themselves having to make a difficult choice, especially in terms of half sizes and compatibility with foreign measurement systems.

and Under Armor, in the new technological concept, capable of combining 3D printing and shoes. Each of these multinationals has proposed a prototype of a shoe with a plastic sole made entirely with 3D printing techniques, and the future holds many other innovations.The application of rapid prototyping logic to the world of footwear seems to be an ideal solution for the most common problems .The first thing that comes to think of a shoe is the first fundamental advantage: the size. Surely many of us will have found themselves having to make a difficult choice, especially in terms of half sizes and compatibility with foreign measurement systems.