CNC Milling Services & Titanium Milling

What is CNC Milling?

CNC Milling is an automated process through by using a various of cutting tools to remove the material off from original block to obtain the shape and size of physical part .It is a type of rapid manufacturing process to make precision metal or plastic parts with tight tolerances .

The first step is to fast cut off a large amount of material as quickly and much as possible to improve the production effective. In the finishing phase allows, by removing a smaller volume ,cut slowly ,to obtain a whole part with dimensions, tolerances and roughness of the surfaces.

In CNC milling process, the machinist inputs the instructions on the computer that controls the machine running, these instructions called G codes or NC codes define the geometry of the work piece and the cutting tool path as a grid of points easily traceable by a calculator. then the machine can run autonomously, and for the machinist it also simply checks the production process ,thus ,it is able to reduce the potential for the factor of human error ,while increasing reliability and repeatability hugely .

The characteristics of the CNC milling services make that it can be ideal for the production of limited quantities orders, prototype parts and customized low volume production components. Actually CNC milling is a machining method that extracts material from a workpiece and creates a custom-designed part or product using computerized controls and rotating multipoint cutting tools. This process is appropriate for machining various materials, including metal, plastic, glass, and wood, and manufacturing multiple custom-designed parts and products.

What is The Difference between CNC Turning & CNC Milling?

While the primary goal of both is to extract or remove material from a workpiece, CNC milling and CNC turning operate in somewhat different ways to machine a specific component. The machine rotates the cutting tool, whereas the workpiece remains stationary in CNC milling operations, while the workpiece rotates, whereas the static cutting tool performs the process in turning operations.

While the primary goal of both is to extract or remove material from a workpiece, CNC milling and CNC turning operate in somewhat different ways to machine a specific component. The machine rotates the cutting tool, whereas the workpiece remains stationary in CNC milling operations, while the workpiece rotates, whereas the static cutting tool performs the process in turning operations.

However, that isn’t the only distinction between the two. CNC Milling and Turning are both used to create various types of end pieces. CNC milling gets preferred for parts that need complex shapes such as squares or custom ones. Turning, on the other hand, is used for sections that require symmetrical and cylindrical shapes.

Even though CNC Milling and Turning yield very different results, they both allow you to carve out patterns and information that would be impossible to achieve by hand. You can use a precision machine with almost any component you like by combining the strength of both.

Why Choose CNC Milling?

There are several explanations why CNC milling technology gets widely recognized as one of the most dependable methods of producing parts from a wide range of materials. Some of the most important benefits of this concept are:

There are several explanations why CNC milling technology gets widely recognized as one of the most dependable methods of producing parts from a wide range of materials. Some of the most important benefits of this concept are:

Unmatched Precision

The accuracy and precision with which CNC milling can operate are unparalleled globally, which is why it gets used in fields such as aerospace and medicine, where it must perform every detail without error.

Longevity

Since CNC milling machines can operate almost entirely on autopilot and do not require much human intervention, they can run for days without stopping, producing parts continuously and with the same precision.

Fewer Personnel

Since CNC milling get based on an automated process, fewer people are needed to track and operate it, resulting in improved productivity and lower production costs.Maximizing the value of the enterprise.

Advanced Possibilities

CNC milling machines will outperform the most qualified technicians operating manual machines due to advanced automation software and design software, even though the manufacturing process is identical.

Consistency

Since the CNC milling process is mainly automated, it produces remarkable consistency even though the staff handling the tools changes. It can avoid a lot of human factor problems.

Different Types of CNC Mill

We have a variety of cutting-edge 3-axis, 4-axis, and 5-axis milling machines. Understanding which type of machine your component will get manufactured on is crucial for optimizing your design as a designer. When designing a CNC machined component, you might not have considered the type of machine your part would be machined on, but the complexity and type of geometry you may design can vary depending on the device.

The critical distinction between 3-axis, 4-axis, and 5-axis machining is the degree of complexity with which the workpiece and cutting tool can shift relative to each other. The geometry of the final machined part can be as complex as the motion of the two pieces.

3-Axis

The most basic method of machining, in which the workpiece gets kept in a single position. We can move the spindle in the X, Y, and Z linear directions. 3-axis computers get commonly used to machine 2D and 2.5D geometry. In 3 axis machining, all six sides of a component can get machined, but each side needs a new fixturing setup, which can be costly (more on that below). Only one side of the component can get machined with a single fixture rig.

4-Axis

It introduces a rotation around the X-axis known as the A-axis. The spindle has three linear axes of movement (X-Y-Z), similar to 3-axis machining, plus an A-axis caused by workpiece rotation. There are a few different configurations for four-axis machines, but most are of the ‘vertical machining’ kind, in which the spindle rotates around the Z-axis. The workpiece is mounted on the X-axis and can turn in the A-axis with the fixture. Four sides of the component can get machined with a single fixture rig.

5-Axis

Depending on the type of machine, these CNC milling machines use two of the three possible rotation axes. A computer can use either an A-axis and C-axis rotation or a B-axis and C-axis rotation. The cycle gets caused by either the workpiece or the spindle. 3+2 machines and continuous 5-axis machines are the two major types of 5-axis CNC machines.

Precision CNC Milling Capabilities

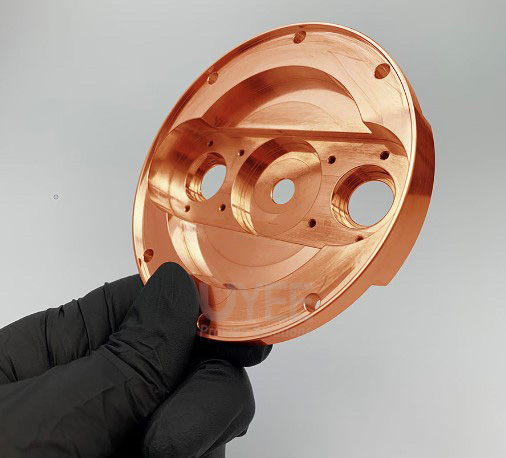

Lots of materials that can be used with a CNC milling process include : Aluminum ,Brass ,Copper ,Stainless Steel ,Titanium ,Nylon ,POM,ABS etc .

In fact, CNC milling services are very fast and affordable .We are able to make complex CNC machined prototype and small batch parts and ensure that they’re machined to precise specifications using multi-axis CNC machining capabilities ,for example ,machining the big size and complicated Aluminum and Titanium .

In fact, CNC milling services are very fast and affordable .We are able to make complex CNC machined prototype and small batch parts and ensure that they’re machined to precise specifications using multi-axis CNC machining capabilities ,for example ,machining the big size and complicated Aluminum and Titanium .

We can handle the max part up to 1500×900 mm in size .Because of our advanced machines and efficiency, they are capable of prototype machining and low volume production quantities of all types of material at a lower cost with rapidly lead time. We keep up with the latest machined technology and are continually improving our work skills ,horizon and expertsie.

UYEE offers a cost effective milling solution for an initial prototype and later short run requirements. We are dedicated to supplying the precision CNC milling services that fulfill extensive needs for accuracy ,precision, quality and value to our clients specifications .and deliver excellent results at honest, fair costs.