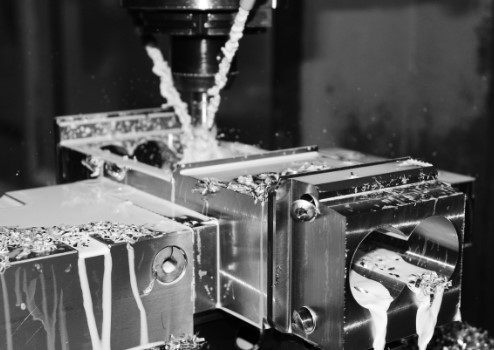

CNC Milling–What You Need To Know

When we talk about CNC machines, one of the types that we must attend to know everything about them are milling machines. Like the other machines that are manipulated by Computerized Numerical Control, CNC milling services machines are an update of conventional milling machines carried out by modernizing wave of recent times.

In basic terms, there is not much differentiation between CNC milling machines and conventional milling machines, so much so that there are special kits capable of converting a common milling machine into a CNC machine. Both formats have the same moving parts, such as the table, cutting head, spindle, and lateral and transverse displacement carriages.

However, CNC service machines do not have levers to operate these parts; instead, they have a screen inserted into a control panel, as well as a metal case to house the electronic and mechanical components of the device. These components include the CNC, which is primarily responsible for the movements of the milling machine.

CNC milling machine components

As we said before, a CNC mill shares some parts with its more basic and conventional counterparts. In the following list we will expose the components of a basic model of CNC machine , highlighting those exclusive parts of them:

- -Column

- –Work piece

- -Strawberry

- -Milling table

- -Cutter head with spindle motor included

- -CNC control panel

- -Hoses for coolant liquid

On the other hand, CNC milling machines have two main axes for movement and two complementary axes for the cutting head.

Function of the Computerized Number Center

The main function of the CNC in a milling machine is to control the movements of the table, the transverse or lateral carriages and / or the spindle along the main axes by means of numerical data. Controlling the movements requires an almost perfect synchronization of all the components that allow the execution of the CNC process, such as the following:

- Axes of displacement, main and complementary.

- Transmission systems

- Clamping systems for parts

- Tool changers.

CAD and CAM programs

The use of CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) programs is practically mandatory on all CNC milling machines. The intervention of each one facilitates the manufacturing process in an unequaled way. We will detail below the function of each one, also including the control software:

- CAD: It is responsible for the design of the piece.

- CAM: It takes care of the calculation of the displacements of the axes for the machining of the part, in addition to adding the speeds of the turns and the various cutting tools.

- Control software: Each CNC milling includes its own. It receives the commands from the CAM program and executes the orders to move the moving parts of the milling machine according to these commands.

CNC milling services machines are adapted to milling profiles, cavities, surface contours and other operations. The milling table generally requires manual control of two or three axes of travel for the table in this type of work. However, depending on the complexity of the job and the type of machine, the process can be completely automatic.

Differences between a CNC milling machine and a conventional milling machine

An advancement of the CNC machining services over the conventional milling machine is the ability offered by the computer that controls them to carry out movements that cannot be performed manually, such as circles, diagonal lines and complex three-dimensional figures. It should be taken into account that a CNC machine allows the programming of the milling operations through numerical codes, to execute them by themselves without the need for an operator to handle them.

The computer of a machine controls the position and speed of the motors that drive the axes of the machine; as well as the movement of the table, the carriage and the spindle. An advantage that enables uniform production, through improved precision, as well as the quality of the final part.