CNC Plastic Machining –Perfect Solution For Prototyping and Low Volume Production

Plastics have come into our lives for many years now and have become such a part of our daily lives. However, plastics remain a really interesting technical solution which today exhibits amazing characteristics. These materials today cover a very wide range which therefore makes it possible to respond to many user issues, to the point that some suppliers are now developing specific plastics for each application requested in response to aesthetic and technical specifications. It has the added benefit of being formed in different ways; molding ,thermoforming, blowing, machining, etc.

Plastic machining, a relevant solution:

Usually, the plastic product is molded according to mass production forming processes ,thus making it possible to manufacture the same part in a repeatable manner at very low production costs. These processes make it possible to easily produce billions of parts. However, machining remains one of the processes for working the plastic to give it the desired shape. CNC plastic machining is easy and the diversity of plastics and sources makes it easy to find a technical solution to your expectations.The most important is that when you are looking for short run production ,in the meantime,the plastic part can not be made by 3D printing , machining will be very useful ,or we can say it is necessary.

Plastic machining helps to reduces costs:

Most of the time, CNC plastic machining is of interest in the production of prototyping and low volume manufacturing parts. It is favored over other processes because the machining has no fixed start-up costs, or very low compared to other forming processes. This therefore makes it possible to follow the development of a product, and to release different versions of the same product in a prototype and product development phase .

Machining can also make it possible to validate part geometry before launching production tooling with a view to controlling a schedule and a budget. Most of customers often use 3D printing or CNC prototype machining before launching and developing the production tooling to verify that the part meets their expectations in order to avoid or to limit as much as possible the subsequent retouching on the tooling leading to longer production times, additional costs and premature wear of the tooling .The diversity of sources and types of plastics makes it possible to ensure a supply in the right format (bar – plates – sheets – panels – etc.). Thanks to this multiplication of sources, it is possible to reduce CNC machined times and costs, to offer you an economical and inexpensive solution.

Take PPSU prototype machining as an example :

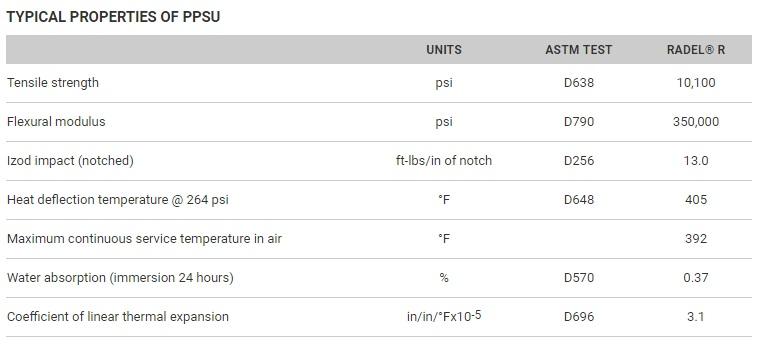

PPSU (Polysulfone) is an unfilled amorphous thermoplastic with excellent mechanical, thermal and electrical properties. PPSU distinguishes itself from PEI and PSU by a better impact resistance and chemical resistance. Also, the material exhibits superior hydrolysis resistance, in fact, it can be safely said that PPSU has virtually unlimited steam sterilizability, making it a very popular material for medical and pharmaceutical equipment that requires frequent steam sterilization.

Due to PPSU High softening temperature, relatively high cutting available Speed does not cause stickiness. The inherent toughness of these materials allows deep and smooth cuts without chipping or threshing. If cooling is required, the effect of spraying water is very good. . It is recommended to use a cutting speed of 150 m/min to 600 m/min and a feed rate of 0.05 mm/rev to 0.25 mm/rev. Milling can be completed at high speed without coolant or lubricant. The cutting tools used for aluminum machining work well. For example, a 13 mm wide and 2.5 mm deep groove can be end milled at a feed rate of 115 mm/min and a speed of 1,750 rpm.

Above image of showing is CNC plastic prototype in PPSU material which we made for one of our customers in the past years. It applied for the kitchen device, when customer demanding a few pieces for test and checking the design CAD model during new product development phase. Obviously it’s impossible to be molded or 3D printed .Currently 3D printing can not work with PPSU material .It’s a type of not commonly used engineering material .and very expensive .So CNC machining is the only one choice .

Conclusion

Today,With the continuous innovation and globalization of 3D printing technology,it has been widely used in many sectors,from a small medical component to house building .However ,we can not still leave CNC plastic machining technology due to it’s quickness ,efficiency as well as almost no limitation on materials choice .