Why Consider CNC Machining for A Prototype?

CNC Prototype means that building prototype through by CNC technology .It can be used to create plastic prototypes and metal prototypes ,even foam prototype is also available. that allows your design work to closely or the same as the end product feature, and also ,it can give designers the enough space to adjust and optimize design during CNC Manufacturing process .Now 3D printing has become a popular option for new product development designers.

However ,it is still somewhat limited as far as materials available and surface finished. But CNC Prototyping allows for parts built from a lot of materials and finished options ,the most important that it allows for the test part to be manufactured from the same material as the end products in production process which makes them better suited for any physical testing that may be required ,this is a quite big advantage.

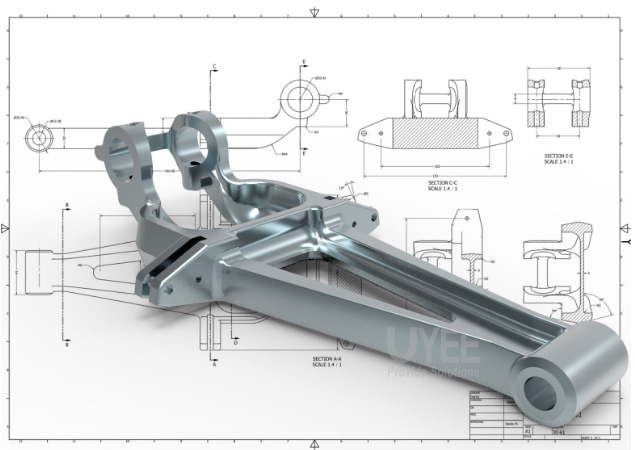

CNC stands for Computer Numerical Control. As a result, CNC prototype machining is a method in which a machine gets controlled by computer-based numerical data entered into the machine. CAD/CAM software is commonly used, allowing machine users to build the required designs and then enable the device to monitor the tool’s movements. The machine may also operate various machining tools such as lathes and drills to achieve the desired results.The method is critical because it enables manufacturing companies to produce product prototypes and other products that meet specific requirements. These metrics include the speed at which the prototype gets made, output, and production costs.

The Advantage of CNC Rapid Prototyping

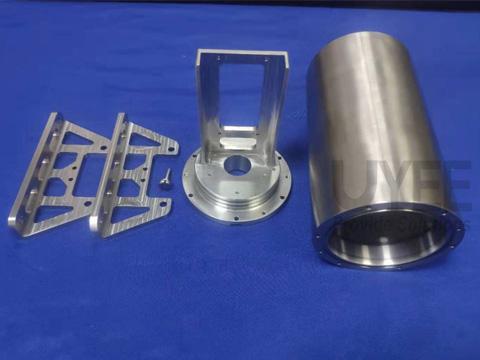

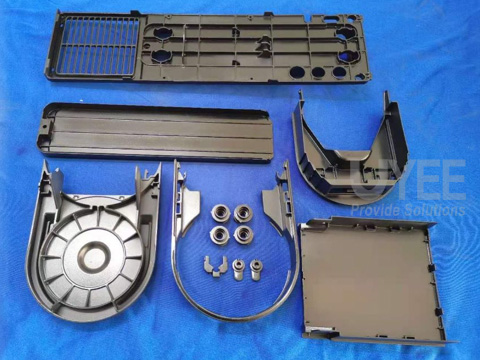

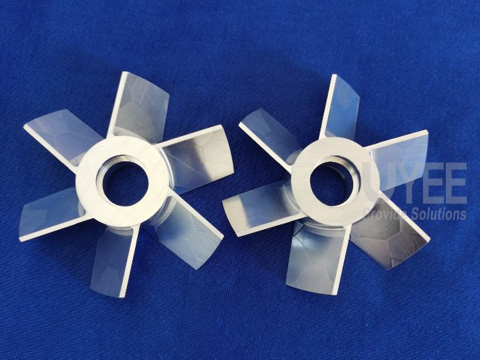

CNC rapid prototyping has been taken by more and more product designers and mechanical engineers . It’s flexible ,smart ,fast ,and capable of short run production . Almost all plastic and metal parts can be machined through by combining CNC milling machines and CNC lathes . According to the different size, structure and complexity of the parts, choose 3 , 4 , 5 axis accordingly . In this way, the production efficiency is greatly improved ,thus, the process of CNC prototyping can help you more quickly to develop your projects with a range of materials option.

Repeatability

Controlled Precision

Material Friendly

Productivity

Fast Turnaround

Cost Effectiveness

The Disadvantages of Prototyping with CNC machining

Despite its benefits, sometimes CNC machining has also some drawbacks as a prototyping process due to the order quantity difference,design diversity,dimensions,and materials optioning. leading businesses to choose a different approach.

Probably more expensive than 3D printing

Sometimes probably the cost of CNC machining plastic prototypes is one of the most noticeable disadvantages. Machining centers are massive pieces of equipment that need more power and human oversight than 3D printers.

Some geometrical restrictions

Even though 4-axis and 5-axis machining centers have a high degree of geometrical versatility, they are not without limitations. Since cutting tool angles are limitless to additive manufacturing processes, they may be more suitable for complicated structures with complex internal geometries.

Waste material

Because CNC is a subtractive process, it requires more material than is used to produce the component. Any of the substances are removed, resulting in metal or plastic chips that we must discard. In contrast, additive prototyping methods do not generate waste material unless the print fails and must get replicated.

When Should You Consider Creating a Prototype With CNC Technology?

CNC prototyping entails taking 3D solid model CAD designs as input and fabricating the component directly from solid material using a computer-driven cutting and milling process. Some also referred to this method as “subtractive” rapid prototyping, in contrast to 3D printing, often referred to as “additive” manufacturing.

The CNC machine subtracts material from a starting material block to produce the final component precisely to the CAD model specifications. This material removal process is efficient, fast, and accurate to demanding specifications thanks to modern CNC machines. We can produce parts from almost every machinable content commercially.

Accessible in a cast or extruded stock, thanks to CNC prototyping’s subtractive nature. It increases material flexibility and provides for prototyping materials that are often identical or quite similar to those defined for production use. CNC manufacturing suppliers have an excellent choice for low-volume customized products and prototypes with precise performance!

How to Get High-Quality CNC Prototypes?

The advantages of rapid prototyping are apparent. Accuracy is critical when producing a product that must follow strict requirements. A prototype aims to create a physical object to help check ,test and approve your product design. However, it should be a precision and real model. For CNC prototyping, which is driven by a computer’s precise skill, turns the every detail of CAD model into an actual part correctly. It is an appealing choice if the company intends to produce goods with extremely complex specifications and little room for human error. This rapid manufacturing approach to prototyping’s quick turnaround time can be a better option for some of projects .

Other prototyping methods exist, for example: SLS ,FDM, but they are limted on materials of option. CNC manufacturing may require a wider variety of materials.From metal to plastic ,wood ,including foam. It has many available choices. Milling, grinding, EDM and turning are examples of prototype machining manufacturing techniques. Each method employs computer-controlled machinery to produce highly precision and informative prototype parts.If you would like to get high-quality CNC prototypes ,a few factors what you need to consider as below:

- Does the vendor have vast experience and expertise in industry?

- Does the vendor have quality control?

- If they have a good communication with you, and respond fast for your questions?

- You need to communicate clearly with the vendor during quoting what you want, such as: tolerances, finished.

- Does the vendor do full inspection before packing and shipping?

CNC Machining Is A Nice Option for Prototyping

At UYEE, when prototype parts are machined, we treat them as the same as a final production run. The CNC programs, fixtures and inspection documents necessary for a production run are also built for prototype. This ensures that there will be the same quality products as prototype after we go into production. From plastic ,aluminum ,titanium ,to stainless steel ,brass ,tool steel etc. UYEE has been offering CNC prototyping services and turning them into production almost 15 years .We offer an outstanding option for CNC prototype and low volume customized products with precision results!