For Industrial Design – The Most Basic Step from Concept to Prototype

The creation of prototype manufacturing is a great step where the idea stops being a simple concept on paper, and becomes physical, becoming the first test of whether an implement is viable. When it comes to industrial design, carrying out a prototype is a task that requires not only imagination, but also extensive experience in the area. This is because some of products in industrial design tend to work in conjunction with molding that is usually extremely expensive, and in case of failure, if you do not have the necessary experience and knowledge, it can lead to millions in losses.

So we can also note that the rapid prototyping has great benefits. If they are effective, you end up getting a breakthrough when performing a task, providing a service, or saving on production. If the prototype is very successful, it can be patented, becoming a great source of income for its designer and creator. However, for the development of a prototype, a certain number of steps are needed to follow in order to minimize the possibility of errors and losses.

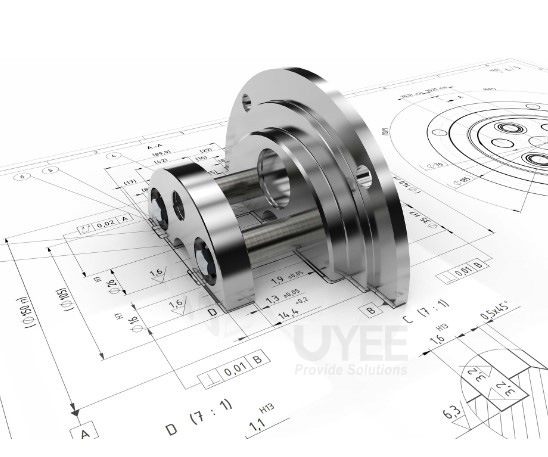

2D Drawing (computer-aided design)

Initially, 2D CAD systems only accelerated the process of producing these design drawings. These tools also make design modifications easier and substantially enhance engineering operations. When 3D CAD systems were introduced in the 1990s, they, too, enhanced processes and designs. Despite 3D capabilities, 2D drawings remain the primary means of transporting a design into a production setting. 2D drawings were vital for most of the contemporary design’s life, perhaps until the last decade.

Before computers, 2D drawings were utilized to specify the requirements of a component completely. In producing a product, such as a bolt or fitting, 2D drawings are utilized as the sole reference. This technique of manufacturing may be traced back to the dawn of technical knowledge. Their history demonstrates their significance; for millennia, 2D drawings were the only means of conveying design information – until CAD arrived.

While there appears to be a declining trend in the utility of 2D drawings in the design world, we will hit an asymptote, most likely above zero, at some time. At this stage, 2D drawings will still be important and valuable in certain ways, but we will spend as little effort refining them or expressing information through them as possible. Historically, we used these drawings to transmit large amounts of part-level data. Because most of this data is now transmitted via CAD models, the only data we must send at a part level is critical.

Creating a draft & CAD model

It is the first step and obviously ends up being one of the most important. It is the elaboration of a draft of the prototype in question, which ceases to be an idea and becomes reflected on paper. In this way the idea becomes a visual manifestation and you can start working on it.

Once you have a draft, you can seek help from product designers so that you can begin to carry out the necessary studies for your recreation. Depending on the area to be taken, it will be the expert in question. After that, the design begins to be studied in order to continue to the next step.

We can also take into account that the creation of a CAD (Computer-aided design) helps us enormously to plan how to build the prototype model. Recall that currently, most of the creation is assisted by means of machinery and molding, so having the design on a computer greatly facilitates the verification work.

Creating a BOM list

For a single component ,it is not necessary, but if it was a whole set prototype model ,it’s needed. The elaboration of a list of BILL OF MATERIALS (BOM) allows enormously the acceleration of the project. This list is a large and extensive dictation where you can see the raw materials, the various components in use, the instructions for the construction of the components, the manufacture, and in some cases the repair of the prototype itself. This list clearly indicates what the materials are, and the different processes for creating the prototype.

The manufacturing processes of building prototype

Currently we can speak of two types of procedure that are considered to be at the forefront. The first is about 3D printing. This procedure uses machinery that, after having the information related to the product, begins to create it from scratch, commonly using plastic and rubber ,metal , which are the most easily moldable materials. The other viable manufacturing process is known as CNC prototype machining. It is widely used when it comes to metalized and plastic pieces, since it works with a machinery making a kind of carving directly on a piece of block. This process is mostly computerized, resulting in a part of the exact size needed. With this procedure, the prototype will be exactly as planned.

Having already chosen advice for the design and the material of the creation, you should turn to a prototype manufacturer capable of producing the prototype. Choosing a manufacturer is extremely important, since they must be able to carry out the concept studied, the applied design and finally transform it into the part in question.

New Manufacturing Methodologies

You, as an engineer, know how far modern Production has advanced, with workflows going against even only a decade ago. Additive manufacturing is the hot new production technology that everyone is talking about when revolutionizing the design world. Perhaps the most significant shift in the engineering design world has been brought about by gradual, incremental technical advancements in manufacturing processes.

CNC machining services and other kinds of subtractive manufacturing these manufacturing processes used to be analog, requiring the input of a trained artisan to obtain a high output. Because of the requirement for human controls, Sometimes we had to develop 2D drawings except building CAD model .

Conclusion

The experience becomes necessary. UYEE is one of the many prototype companies also focused on the manufacture of the designed prototypes. Through the design, and its extensive experience, it ends up creating an exact prototype to the desired one taking into account measurements, hardness, finished and tolerances of each piece. In this way, the prototype ends up fully fulfilling the work for which it was designed, and can be evaluated for later mass production.

If the steps are followed to perfection, the prototype will yield great benefits. Therefore, it is extremely important that the appropriate steps be followed: the slightest failure will end up resulting in a deficient prototype, which will end up being discarded even though its concept is perfectly viable.