How To Find Excellent Prototyping Services Manufacturer In China?

Rapid Prototyping Services allow to quickly come with the physical product model. This model acts as the concept proof and is very helpful even for functionality testing before starting any significant investment for expensive tools like injection molds. It offers the best prototype solutions. Here is a list of some key technologies:

- 3D printing for metal and plastic

- CNC Prototype machining

- Vacuum casting molding for plastic

Steps involved in rapid prototyping

Here is a sequence of steps involved in rapid prototype machining services to get the best and completed machines and CNC parts delivered at doorsteps:

- Uploading a CAD file: To start with the process and utilizing the services, you must first fill up the details and upload a 3D CAD file to provide access to the service provider.

- Quoting and analysis of design: You will soon receive a quote from the chosen Rapid Prototyping Services provider and then get the design for manufacturability analysis (DFM).

- Confirming order: After reviewing the quote, you must place the order and then let the service provider start with the entire manufacturing process.

- Getting the prototype parts delivered: After reviewing the quote and then placing the order, the chosen service provider will complete the manufacturing process and then deliver the manufactured parts at your doorsteps (if you want).

When will I require Rapid Prototyping Services?

Tools that can be utilized for large production can be costly. Moreover, you cannot do modifications too once it’s already done. However, before a mold is available for production, it will require up to two months.

You can’t accurately flicker about with various designs based on the difference in their costs and required time to develop any particular mold and different tooling. That’s more where rapid prototyping reaches the spot.

Assume that you have an idea for the product and you desire to advance funds for any new Prototype or model. Or, possibly you need to test and jerk the form and characteristics of a new product conception. That is when rapid prototyping makes a lot of sense.

How to find excellent Rapid Prototype Company In China?

Today’s world is flooded with more rapid prototyping companies across China that give various kinds of prototyping services, such as 3D printing, CNC machining/turning, rapid tooling, sheet metal, Prototype Machining, etc.

Most of the companies are trying to catch abroad customers to increase their business. But only few maintain the standard of high-quality to construct well-built models or low amount composition of products to put into and examine the market.

Above all, high-quality, instant delivery and flexible service are challenging to find in one supplier. So, here are the critical tips mentioned to pick a trusted rapid prototype services provider company in China.

-

Check out the Industry Experience

When you scan for an abroad supplier, analyze based on Experience. For example, for a complicated project with several parts, materials, and finishes, if you operate with a skilled prototype developer, they can give all that you need to; transform your approach into an excellent prototype or a machined model part.

So, go for the proper manufacturer to save your money and time and accomplish your contraption and concept. You will professional services too.

-

Look for High Quality Services

While scanning for a trusted manufacturer, several abroad clients have to face some difficulties and problems. Because they are not aware of what the manufacturer can offer, they are unsure whether they will be delighted with the quality after getting the finished goods. While picking a good and decent supplier, never prioritize rate over quality. You should look for quality above all.

An investment into the quality manufacturer will add valuable benefit to your business complementing your product and services. Especially, note that, the company has a team of certified manufacturers who can contribute significantly for the custom based machining parts. If required you can check their profile online and review their testimonials to get a better insight for rapid prototyping services.

-

Quick Turnaround

Every business has its own urgency. So when you are looking for an excellent prototyping service manufacturer in China, note their turnaround time. You can seek quotations of a few manufacturers in order to get an idea of their quick services.

Rapid prototyping must be as instant as accomplishing the task and providing the finished prototype products in only a couple of days or within a week. This is necessary for saving a large percent of the overall cost.

-

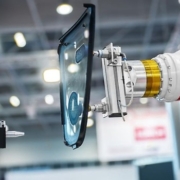

Advancement with technology

When you are looking for an excellent rapid prototyping service manufacturer in China, it is advisable to connect with a tech savvy company. They must be abreast of the current marketing conditions and the latest technologies to pace up with the requirements of multiple industry vertical. You can connect with UYEE Prototype now you for an incredible prototyping and CNC machining services.

What more to look for while choosing the Rapid Prototyping Services?

Apart from the aspects mentioned above, apart from analyzing the prototype development, here are some more things that you must look for while selecting the best out of the available Prototyping Services across China and abroad.

- Lower volume manufacturers: Apart from the Prototype Services, you must also look at whether the service provider or the chosen company also offers lower volume manufacturing services for numerous industries, including medical, automotive, aerospace, etc. The chosen company must also be experienced with prototype making, and pressure dies casting, rapid tooling, aluminum extrusion, and plastic molding.

- Surface finishing: Look for the service provider that excels in manufacturing prototypes and offers smoother surface finishes for the developed parts. The company must be utilizing various types of painting, polishing, screening, and other measures for the same.

- Outsourcing: Overall, the service provider must also have a facility for outsourcing manufacturing services like forging and investment casting so that you can utilize the service whenever and wherever required.