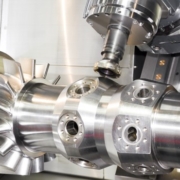

Selecting the Right Cutting Tools For CNC Aluminum Machining

Aluminum is the most commonly machined materials because most types of the material have outstanding machinability and are therefore widely used in manufacturing. As a result, competition for CNC Machined Aluminum can be fierce. Understanding the fundamentals of tool selection, running conditions, and advanced aluminum milling techniques will help machinists gain a competitive edge.

Why choose Aluminum for CNC machining?

Aluminum and its alloys need much less cutting force than steel, so the cutting edge of a milling tool experiences relatively low mechanical loading. Since aluminum has high thermal conductivity, the chips created when machining aluminum pass a significant amount of generated heat, resulting in significantly reduced thermal loading of the cutting edge. Because of these properties, Aluminum CNC machining requires extremely fast cutting speeds and feeds. However, this does not guarantee that machining aluminum will be as easy.

Material Properties

Aluminum is a highly malleable, workable, and lightweight metal. This material’s components can get used in virtually every industry. Furthermore, because of its low cost and versatility, aluminum has become a common material for prototypes.

Aluminum comes in two primary forms: cast and wrought. Wrought aluminum alloys are usually more robust, more costly, and contain fewer outside elements. Wrought aluminum is also more heat resistant than cast aluminum and more machinable.

Cast aluminum has a lower tensile strength but a higher degree of flexibility. It is less expensive than Wrought and has higher concentrations of outside elements (silicon, magnesium, etc.) in its alloys, making it more abrasive.

Tool Geometry

There are coating options available for aluminum tooling, including the common gold-colored ZrN (Zirconium Nitride) and the lesser-known but highly effective TiB2 (Titanium Diboride). Uncoated tooling can also provide good machining results. However, knowing the correct flute count and helix angle for your process is the real secret to high-performance machining in aluminum.

-

Flute Count

End mills for aluminum are mainly available in two or three flute configurations. Higher flute counts would make it impossible to evacuate chips efficiently at the high speeds possible in aluminum. Because aluminum alloys leave a large chunk, and chip valleys on end mills get smaller with each additional flute.

End mills with two flutes have traditionally been the preferred alternative for aluminum. On the other hand, three flute end mills have proven to be more effective in many finishing operations, and with the right conditions, they can also act as routers. While much of the debate between two and three flute end mills for aluminum boils down to personal preference, the process, rigidity, and desired material removal rates may influence tool selection.

-

Helix Angles

The helix angle is the angle generated by the centerline of the instrument and a tangent straight line at the tip. Aluminum cutting tools generally have higher helix angles than standard end mills. Helix angles are typically 35°, 40°, or 45° specialized in aluminum. Variable helix tools are also available, and they are excellent for minimizing chatter and harmonics while increasing material removal speeds.

For conventional roughing and slotting applications, a helix angle of 35° or 40° is a reasonable option. A 45° helix angle is the preferred option for finishing. It is also the preferred choice for High-Efficiency Milling tools because the high helix angle wraps around the tool faster and produces a more aggressive cut.

Tooling Options

When machining aluminum, regular 2 or 3 flute tools will usually suffice. However, for some applications and system configurations, there are some additional tooling choices to consider for improved performance.

-

Chipbreaker Tooling

Efficient chip evacuation is one of the most critical factors to remember with CNC Machined Aluminum (and many other materials). It can evacuate chips reasonably well with standard 2-3 flute end mills operating at recommended speeds and feeds and with sufficient chip loads. Three flute chip breaker tooling, on the other hand, can be used at higher speeds and feed rates for even better efficiency. The offset chip breaker geometry produces more minor chips for optimum evacuation while maintaining a semi-finished board.

These tools are ideal for more specialized tools, such as High-Efficiency Milling, which is another essential tool for a good aluminum machining experience.

-

High Balance End Mills

High balance end mills get intended to improve efficiency in highly balanced machining centers capable of high RPMs and feed speeds. These tools are precision balanced and designed especially for high-velocity aluminum machining (up to 33,000 RPM).

We provide CNC Aluminum services with tools in traditional two flute styles and coolant-through three flute styles for reduced heat, improved chip evacuation, and faster material removal speeds. These methods, including chip breakers, are also ideal for High-Efficiency Milling tools.

Bottom Line

To summarize, milling aluminum is a simple process if done correctly! For good results, use an effective cutting technique and properly selected milling tools. Please note that the machinists play an important role in whole machining process .