Why You Need Rapid Prototyping?

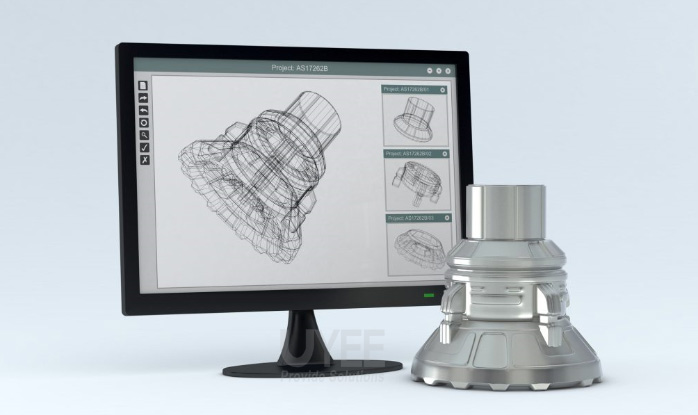

Simply say, Rapid Prototyping is a technology that turn the CAD model into the physical prototype quickly .When a real prototype in hands ,you are able to check and test all the features quite conveniently ,from material to dimensions ,and appearance. Obviously creating prototype is the most economical way helping designers and investors to check and test before molding or other ways running mass production. It has been widely applied on all of kinds industry areas, defense, aerospace ,automotive ,medical etc.

Rapid prototyping is a relatively modern concept that rapidly produces prototypes to visually and functionally validate an engineering product design.Careful consideration of the five primary factors, namely purpose, quality, quantity, complexity, and cost, will significantly impact prototyping performance. A prototype is a dummy version of the end-product used to validate the design, test the technology, or analyze the working theory and offer product specifications for an actual functional device in the sense of engineering product design.

CNC Machining Involved In Prototype Making

For most of Western people when talking about rapid prototyping ,usually it refers to 3D printing ,SLS ,FDM etc technologies .However ,today CNC Machining technology is more and more universal ,especially in China ,most of prototype manufacturers have CNC machines in their shops .So that means CNC machining process is involved in rapid prototyping already. For now you could often hear people talking about CNC prototype machining ,after all ,3D printing has still too much limit on some special materials and surface finished ,specially for some metal prototype.

CNC prototype has more big advantage on tolerances ,threads ,and better surface finished. But if you are not sure which process is more suitable for your project when you are getting a quote ,then,you had better make a discussion with the prototype manufacturer according to your design,specification and request who will help you to make the right decision and custom prototype with the most economical way .

Advantages of Rapid Prototyping

Who will be possible interested in this rapid manufacturing services? As an industrial product designer, engineer, or probably some investors who are running business with the new product development relatedly, then, prototype will provide you with numerous benefits, including:

- The opportunity to quickly discover and cost-effectively realize ideas. Quick production times could allow projects to progress well beyond the simulation of an only concept. It will be more convenient to understand the whole design manufacture process and explore the function of part, no matter a single one, or multiple pieces.

- Designs adjustment and implement modifications constantly which are able to make for better product assessment and practical application testing. This offers a blueprint for developing and optimizing the fabulous ended product before moving to the public, making sure ultimately the design is refined and error-free.

- Obviously a CAD model in the computer showing cannot present the design concept clearly due to you cannot touch , and feel it .So rapid prototype realizes this to help customers better to clarify it along with a physical part on your hands .

- By removing the need for setup and tooling relatively. It make sense significantly to help customers to save money and shorten time through by using a prototyping technology. Imagining if you would create a mold directly ,how much will it cost you ?

Why Choose Our Prototyping Services?

No MOQ Limited

We can accommodate one-off prototypes and low-volume components. Whatever is the size of your order, we can handle it.

Fast Turnaround

Our manufacturing capabilities and expertise allow us to complete your rapid prototyping projects in a matter of days.

Tight Tolerance

We provide precision parts with tight tolerances to the aerospace and medical industries.

Competitive Pricing

We have developed an efficient rapid manufacturing system, allowing us to offer competitive rates that any offer can match.

Experienced Engineers & Technicians

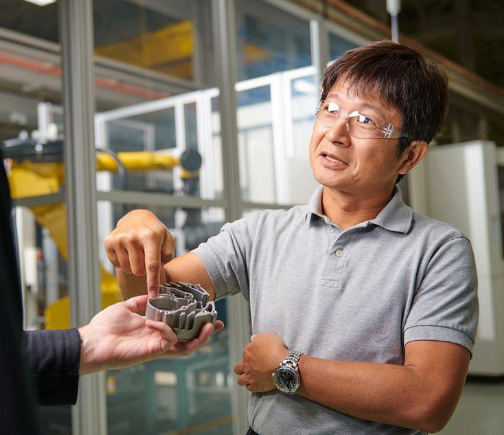

Our specialist team is extensively experienced and able to perform even the most complex challenges in different fields.

Our Rapid Prototyping Services

Quality manufacturing gets done correctly – every time! Our rapid prototyping services, mainly CNC machining, vacuum casting, rapid tooling, and sheet metal fabrication, ensure that your designs and ideas become a reality in a matter of days. You would be able to personally inspect your product’s design and functionality before getting sent to mass production.

Our expert team will assist you with every step of product growth, from design optimization to determine your production needs’ most effective direction. With our rapid manufacturing expertise, cutting-edge rapid prototyping technology, and an infinite supply of materials, there is nothing you can’t produce with us by your side.

During product design and development stage ,probably you will meet some problems if you don’t have too much about rapid prototype knowledge ,here our team members not only providing manufacturing services ,but also coming up with a solution to help you to fix the issues .

-

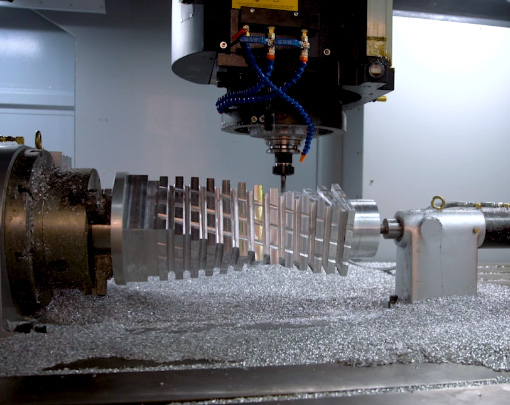

CNC Prototype Machining

We offer precision CNC machining services such as milling, spinning, EDM (electrical discharge machining), and wire EDM, as well as surface grinding. We can handle all technical aspects of making your prototypes and parts with our precision 3-, 4-, and 5-axis CNC machining centers, along with other specialized capabilities and our professional staff, so your team can concentrate on getting your product to market. We are the best place to visit if you need a precision machining company for plastic and metal CNC machining components.

-

3D Printing

We offer various high-quality 3D printing (additive manufacturing) services, such as SLA, SLS. It enables 3D printing of plastics , as well as options for prototyping and manufacturing. It is a perfect way to make one-of-a-kind components or small batches. We can use it to produce intricate geometries that would be impossible to realize using conventional manufacturing methods.

-

Vacuum Casting

We can handle any of your plastic and rubber prototype request through by silicone molding which is a soft and fast tooling. With years of skills and experience in the rapid manufacturing industry, your plastic products will be produced with the highest standards while remaining cost-effective.

Vacuum casting is a also good method for producing small batch rubber components, and it is perfect for creating high quality prototyping parts in quantities ranging from from dozens to hundreds wth fast turnaround.Obviously steel mold is unavailable for this .

-

Rapid Tooling

Rapid tooling, also known as rapid injection molding ,including silicon molding. It is a fast and cost-effective method of performing low-volume production for various plastic and rubber parts. It is often used for rapid manufacturing needs in a short timeframe or fill the gap between mass production and prototype parts. We combine our expertise, technical skills to deliver high-quality low volume production products with fast lead time.

-

Low Volume Manufacturing

Many designers, developers, and companies see prototyping and mass production as the primary goalposts for product creation. However, there are periods when low-volume production is the best option for those that need small amounts of finished parts, ranging from a few hundred to hundreds of thousands. By using a skilled prototyping and manufacturing service such as ours, our customers gain the opportunity to obtain the exact amount of parts they need, regardless of the final count.

From the initial product design analysis and quotation to the quality inspection of your newly produced parts, we will be there to assist you every step of the way. We not only specialize in prototyping and mass production, but we also specialize in low-volume manufacturing.

Providing A Full Range of Rapid Prototyping Services

Today there are many technologies creating prototype fast .We offer a full range of rapid prototyping services to help our clients make a correct option according to their relative design and requirements .Our technologies include 3D printing ,CNC machining ,Silicon molding ,Sheet metal ,Assembly & Welding .We will use different technologies according to the quantity ,surface finishing, lead time and functional requirements for the prototype.