Advantages of Custom CNC Machining Services

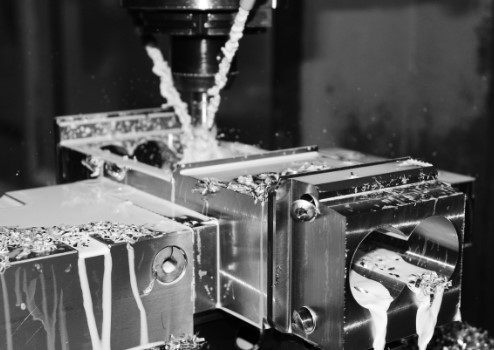

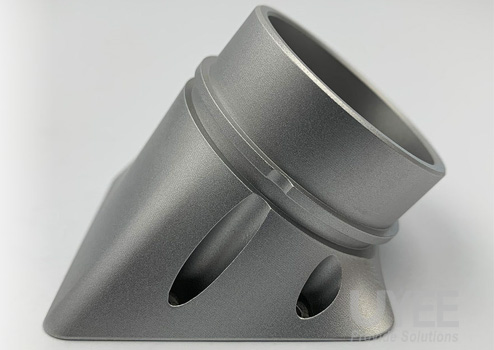

Custom CNC machining requires manufacturing parts has become universal in industry that do not exist anywhere else. It can include any CNC machining, such as turning, milling, and EDM, that a company may provide. A gear, for example, can be a custom part. However, you may require the gear in a nonstandard size or material, or it may be a novel invention that suppliers do not yet have, necessitating customized production of the item.

What Industries Necessitate Custom CNC Machining?

Almost every industry necessitates customized CNC machining. It is useful when a company needs accurate CNC parts that are sometimes difficult to produce using traditional methods. Custom CNC machining components are requested in a variety of industries, including:

- Aerospace & Defense – items created for this industry include flight safety devices and other aircraft-specific equipment.

- Agriculture – items specialized for this industry include farm vehicles and farming gear.

- Automotive – motorcycle parts, metal prototypes, the plastic shell of lighting and other automobile related accessories.

- Construction – In this case, you may require heavy structure equipment that is not available elsewhere, especially if your construction is a one-of-a-kind design.

- Firearms – any part, large or tiny, required for ballistic devices

- Electronics – this includes the manufacture of semiconductor parts, enclosing enclosures, and other items.

Here are a few benefits of employing custom machine parts

It might help you save time when looking for the right parts

One advantage of adopting bespoke CNC machining is for manufacturers looking for parts that are no longer in production. Customizing this part is simple with CNC machines, and you won’t waste money or time seeking one. They can also find used components, albeit they may not be as reliable as the original part.

A large amount of time will be lost searching for the correct part, causing the manufacturing schedule to be disrupted. Finding the correct machine shop that can modify and manufacture the parts you require in a fraction of the time it takes to seek the appropriate replacement parts.

The Part’s Specifications are on File

The specs are retained on file after the first order is completed. If replacement parts are required, the corporation can return to the CNC machine facility and get the data. This convenience comes in handy while working on a tight deadline. We cannot find this level of dependability in any industrial technique.

What might a faster turnaround mean for your company? It implies that if a component fails unexpectedly, your machine will not remain idle. Suppose your customer forgets to make an order and you don’t have a spare. In that case, you can utilize Custom CNC machining services to get the component and the business rolling again – no more delivery delays.

Keep the Production Schedule

Even if the machine is not operational, you must still compensate the personnel for their services. And for every hour you have to wait, you lose a large sum of money. However, if you form a collaboration with a skilled CNC machining facility, you will be able to obtain the item you require promptly. Moreover, it means you can get your computer up and running quickly and adjust for any little delays.

It may be able to reuse a part that you already have

You’re probably unaware, but your CNC machining business has the equipment to change the product you already have in stock. So even the machine you trashed could have the part you require with only minor alterations. If this is the case, restarting activities as soon as feasible can save you time and money.

Eliminates the Need for Prototypes

Prototypes are required for the CNC machining process. These are expensive and time-consuming to design and develop. When you employ Custom CNC machining services for the parts you require, you will have a digital copy of the product that will start the machine. It eliminates the need for expensive and time-consuming prototypes. It will save your company valuable production time while you wait for the parts. The time and effort saved in locating a new item can be invested in other elements of your business to help it develop.

Improvement of the Quality of Parts

CNC machines are well-known for the accuracy and consistency of their produced parts. It is because these machines can perform the same task again without error. However, even if the operator is extremely attentive, manual machining generates differences and inconsistencies in product quality. Therefore, you can acquire only parts when you use custom CNC machining.

Because custom machining services offer numerous benefits, they can also have drawbacks. For one thing, the rate of CNC machining is higher than the rate of manually operated equipment. However, the advantages may outweigh the disadvantages. Getting a new item can also mean less disturbance to the manufacturing plant. It simply means that your losses will be modest, and your revenue will be sufficient to cover the costs.

Manufacturers would not receive the parts they require on time if it were not for bespoke CNC machining, saving them time and money. Moreover, more industries will continue to seek customized CNC machines to achieve the desired outcomes, implying that customized CNC machining is here to stay.

Why choose us for custom CNC machined parts

- Our simplified approach, which we established over two decades of experience

- Full-service bespoke and in-house manufacturing, fabrication, and welding capabilities

- All work is done by people who are highly qualified and experienced.

- Safe and green business practices aid environmental sustainability.

- Low-cost solutions that help you save time and money while also increasing productivity.

If you’re looking for a partner who can assist your company in lowering total costs and enhance efficiency, look no further than us. We provide CNC machining services in the south of China, backed up with customer care and support committed to your complete satisfaction. As a result, you get the bespoke machining services you need at competitive pricing that benefit your bottom line.