How to Select A CNC Rapid Prototyping Machine Shop?

A CNC shop is a structure where machinists and design engineers use prototyping equipment to make machined items. Depending on the capacity of the company, these CNC milling services can be large or tiny. Rapid CNC machining has components for cutting, sculpting, drilling, and creating 3-D objects from thick materials like plastic and metal.

They use design systems to develop the design formats for rapid CNC machining and the subtractive technology they use to manufacture these components. These CNC milling services and shops have evolved from ancient, crude production plants to cutting-edge prototyping facilities where manufacturers can make sophisticated prototyping components with extreme precision. Thus, a few factors that you need to consider when you are looking for a CNC rapid prototyping machine shop as following:

How to Judge When Selecting a CNC Machine Shop

When looking for the best CNC milling services to complete your CNC projects, you must examine a few key elements. Not all machine shops provide the same level of service; some are more suited to specific needs and industries than others. Before approaching a rapid CNC machining business, think about the following:

- Design Rights Protection: In reality, these CNC manufacturers sign an NDA that binds them to keep CAD design formats confidential. Many manufacturers are willing to follow this agreement for the formal business.

- Competitive price: CNC shops charge differently depending on their level of knowledge, experience, outcomes, human resources, and machining equipment. Quality comes first for a designer, followed by pricing. Usually excellent CNC milling services supplier could offer high-quality parts at a reasonable cost.

- Excellent Customer Service and Experience: Reputable rapid CNC machining shops strive to provide high-quality items while providing a memorable customer experience. To find such companies, you should meet with the manufacturer in person.

Choosing a CNC Service Provider Based on the Technology Employed

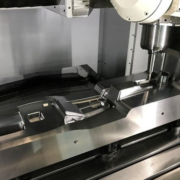

It’s a good idea to check the prototyping tools a CNC company uses to cut, bend, mold, and form prototypes before hiring them. The quality of the job performed is determined by the type of machining tools utilized. In addition, the operator’s knowledge is essential. The following are examples of prototype machines, but they are not exhaustive:

- CNC Milling Centers: These machines contain rotary cutters that use various cuts, such as roughing and threading, to turn raw, solid materials into finished items. To meet the design needs, the ideal CNC milling services should contain these milling machines.

- Lathe: Lathes, also known as CNC turning centers, are prototyping machines that rotate a workpiece around an axis to cut, knurl, bend, and drill a substrate using a cutting tool. It allows cutting machines to easily and precisely create symmetrical prototypes. You can hunt for machine shops that use CNC lathes based on the design requirements.

- Coordinate Measurement Equipment: As a professional CNC shop. Usually they should have them to inspect the parts after machined. This machine measures the geometrical dimensions of machined workpieces to confirm that the manufactured component meets the design specification with zero tolerance for error or variation. As a result, such vendors are capable of producing high-precision, high-quality prototypes.

Quality Control When Choosing a CNC Shop

Quality control must be incorporated into the design and development of prototypes by a recognized machine shop. End products must be defect-free and conform to design specifications in appearance and functionality. Even if they have the lowest prices, avoid CNC milling services that do not meet these requirements.

Supplier must have QC and QA to be in charge of the inspection job to make sure the parts are machined correctly. Customer communication is also essential. A CNC shop must be able to connect with designers successfully and ensure customer satisfaction.

Choosing a CNC Shop for Workplace Safety

A designer should think about the safety of its employees and the safety of the work environment when choosing a rapid CNC machining shop. A reputable CNC shop must provide a secure environment in which operators can use various machining tools. The following parameters might assist clients in determining a machine shop’s effectiveness and reliability in terms of workplace safety:

- Operators must dress appropriately for the task. Clothing that is flammable or loose-fitting is not permitted in a CNC shop. They must wear protective eyewear when working with CNC machines and creating components since shards from machined prototypes can damage them.

- One of the essential considerations for CNC shop employees is their health. This is very important human being concerning .A happy and healthy worker can create more better item .

- Machining equipment should only be operated by experts who have been trained and qualified. They must become acquainted with new tools before using them. Operators should be able to swiftly access emergency exit points and muster areas during emergencies and work-related incidents.

Conclusion

Taking these essential factors into account makes it simple to select the best CNC milling services for a CNC prototyping project. A machine shop should have machining tools, such as electrical discharge machining (EDM) equipment, surface finishing tools, bandsaws, saws, and other associated CNC to go along with the machining equipment mentioned above.