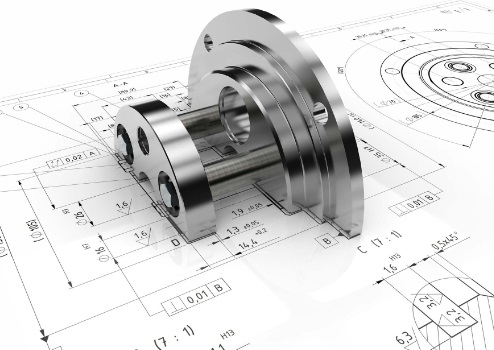

The Advantage of CNC Prototype Machining In Rapid Manufacturing Industry

Nowadays, rapid prototyping technology has become more and more popular. For example, 3D printing is loved by many people. However, due to the limitations of materials, surface treatment requirements, and large-size workpieces, CNC prototype may be the best choice in many cases. For the production and processing of new products, this also benefits from the continuous innovation, development and upgrade of CNC technology, which makes it indispensable in the rapid manufacturing industry. Below we describe some advantages of CNC machining:

1) Material Selection

CNC machining is basically unlimited in the choice of materials. In addition to common plastic and metal materials, wood and ceramics are now more and more used. You can increase the corresponding margin on one side according to the size of the workpiece, and you can cut the original It does not waste a lot of materials when used for the board. However, 3D printing cannot print wood ceramic materials, which contain some special metals, such as magnesium alloys, zinc alloys, etc., so you can see that it has many limitations in the selection of materials.

2) Surface Treatment

Basically, the surface of the workpiece processed by CNC is smooth. After deburring, the corresponding surface treatment can be carried out according to customer requirements, such as :anodized, painted, electroplating, etc. The most important thing is to obtain a high quality finished. This has a great relationship with the performance of the selected material block,which can save a lot of time and production costs.

3) Precision Requirements

CNC machining is very good for the accuracy control of the workpiece. Many tools can be installed on the tool magazine at one time, and the cutting can be selected according to the program path. The programmer can select a specific tool and optimize the program according to the accuracy requirements on the customer’s drawing file. , To meet the accuracy requirements, and the positioning of the workpiece when using the fixture is also very important.

4) Rapidity

For some simple workpieces, such as those without a cambered structure, it may be completed within an hour. After receiving the customer’s CAD drawings, you can immediately prepare materials, program, machine, and run, which is why many products Developers and designers like to choose CNC machining as the production process, especially in the rapid prototyping industry, this function creates high value for the enterprise.

5) Flexibility

For CNC prototype, you can choose to make one, several, or hundreds, but only one program is enough. If you need to change the material later or modify the CAD drawing file, you only need to update the program and adjust the fixture. For example, some holes need to be enlarged, and the grooves are deepened. These changes are more convenient and will not take a lot of time.This will increase the economic efficiency virtually.

6) Quality

The advantages of quality are mainly reflected in two aspects: on the one hand external: according to the above The description, surface treatment and dimensional accuracy can meet customer requirements very well, one the other hand: The mechanical properties of the material, functional testing can meet engineering needs, and at the same time, the tapping requirements for some very hard plastic or metal parts In the CNC machining process, it can be more perfectly reflected.

How Can We Help You ?

We are experts at CNC prototype machining and low volume manufacturing ,if you have some projects which are related with machining services .We can help you within the shortest possible lead times. Please don’t hesitate to contact us for a quote ,send us your CAD files and PDF drawings .