Why Are Custom Prototypes More Efficient To The Future Of Production?

For technology, apparently nothing is impossible, and we always see how it is capable of creating new techniques and ways to achieve a goal in a faster, safer and more efficient way. This is the way we see the world grow today, and the possibilities to create are virtually endless. This behavior has great notoriety in several areas, and one of them is the creation of parts, pieces or complete objects. When prototype technology is born .It is a kind of technological innovation, which has produced great benefits to industrial production, when it is related to rapid prototyping industry ,it created the huge value, because it makes the product design and development be more options .

In the search for the perfect technique to create parts, manufacturers have tried multiple processes, which turn out to be best for one task and another, thus becoming everyone’s favorite. You will know more about the knowledge of rapid manufacturing field through as below.

Why Rapid Prototype?

But, we all know that, before being able to mass produce parts, it is necessary to create one or more prototype parts that will serve as an example to test the object and approve the design in its entirety, this test will determine if the process can be continued, or if there is to make major structural changes or adjust the external shape. This concept about creating a sketch became common among all manufacturers, and for a time this was the premise followed by all, but over time, this alternative began to request some solutions and improvements, as it sometimes presented a large disadvantage and expense.

The disadvantages began when the manufacturers specifically requested some molds or machines to create these sketches, but when some of these were not successful, the company ended up spending unnecessary money on the wrong mold cost, and they had to redo it in order to make more pieces of these. But the solution to these manufacturing problems materialized thanks to the creation of the custom rapid prototypes ahead.

The Solution of Prototype Machining

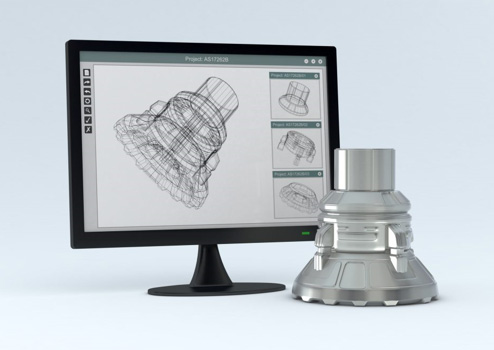

From the beginning, manufacturing has shown multiple ways of creating a piece, either from a mold, or carving it. To perform the molding and cutting of various parts, we can find multiple techniques, and certainly, some stand out much more than others, an example of this is CNC prototype machining, which has been widely applied today in the process of manufacture of multi-material parts. Despite the fact that there were already so many processes to achieve this task, when it came to manufacturing based on metallized materials, it was very difficult to achieve perfection, and although everything was tried to complete a piece with the exact requirements that the client required, the ideal and correct technique was not always found. This is how CNC rapid prototyping suggested as a solution for creating parts from multiple materials, especially from various metals. Contrary to what many believe, sculpting pieces from metal is not as easy as it seems, because it should not be a secret that all metals have different properties, and quite different from each other.

From a CAD model to a real machined part ,in fact ,the process is not complicated , make the programming ,input the CNC machine ,fix the original block material ,set up the cutting tools ,then, start running the machine . Especially for the big metal part ,it has a big advantage to save cost and turn around faster comparing 3D printing .

Prototypes Are More Efficient

Custom Prototypes have managed to position themselves as one of the best solutions for the creation of parts, and it is that they have the ability to allow a very early error detection, and correct it immediately. The versatility of rapid prototyping has allowed everyone to create any possible piece, hitting every corner of it. It should be remembered that the success of prototypes is basically based on two or three premises, for example: prototype manufacturing in 3D printing is done layer by layer, this means that manufacturers will not need any expensive machines that are built specifically for prototyping. On the contrary, you only need a simple machine that is responsible for placing the layers of the requested material, in order to form the specific piece, and best of all, you can form any piece that is required, without the need to change machine, or go through different processes, just one.

In addition to being quite detailed, rapid prototyping also allow for many other tasks, which would not be possible based on other production techniques. One of the advantages that this style of manufacture has over others is that they can easily show the manufacturer the aesthetic appearance that the pieces can have at the end of their creation. Of course, this allows the detection of some unwanted or visually uncomfortable shapes to take a different shape with the correction of some data.

You can also consider having custom rapid prototypes to perform functional tests with the part, that is, the resistance, use, and other similar characteristics can be detailed in the part, either individually, or already assembled with other parts. This is a matter that can also be easily handled by prototype manufacturers, since these prototypes allow evaluating the geometry of the pieces, validating that they are created based on all the other parts, assembling the entire object to perfection, and complying its functions efficiently.

The Advantage of CNC Prototype Machining

The properties of the materials are diverse, so they have different treatments. There are metals like aluminum, which must be treated very precisely, so as not to wear the material unnecessarily, or compromise some part of the piece due to a slightly exaggerated cut, a crack, or a collision between materials. On the other hand, there are materials such as titanium, which require very precise machining, and not only that, but it is also important to know the materials with which the machines that will be in charge of machining will be created, since this material it is quite hard, and almost always wears down machines quickly.

The custom rapid prototype machining was able to control all the processes related to metal machining, applying the most suitable for each one. Prototype machining solved the problem of balancing the way of working on the various metals required by customers of parts manufacturers, and showed the world how easy it could be to manufacture using this method. It is currently the indispensable tool that all manufacturers have, and it is really easy to start a part manufacturing process that is protected from errors. Each time rapid prototype machining is applied, a part is being created that can maintain the initial and equal characteristics of the part that has been determined for manufacturing in large quantities, always respecting the pattern, and achieving the precision of the part.

Today ,people are more eager to appear more precision and diverse machines ,milling and lathe machines .Helping them to achieve their design concept with a productive and efficient choice .CNC machine drives the rapid development of the entire RP industry. Did you check out right now that more and more prototype machined parts are used directly for the end products ? This shortens the production cycle of new product development hugely .

The Universal Rapid Prototyping Services

Although there are thousands of companies that take this and other techniques as the main ones for the manufacture of the first of their products or parts, we are one of the best performing rapid prototyping services manufacturer in this regard. Our expertise and diverse facilities to provide you with CNC machining ,3D printing ,rapid tooling ,sheet metal fabrication as well as all kinds of finished options. So you can trust that your project will be successful from the start, and that you can start mass-manufacturing your products or parts quickly and safely. You can now materialize the manufacture of exclusive and personalized pieces to completely start your business.

Conclusion

In the past, it was really difficult to achieve this with traditional methods, since you had to assemble the product completely, and test one by more of these, without being sure that it would turn out well in the end. Thus, it wastes a lot of time and creates a lot of uncertainty .So making prototypes ahead are the best option for the manufacture of products and parts, it is evident that although there are multiple options for the creation of objects, this is one of the fastest and most efficient ways that there are today. Its effectiveness has been proven time and again, and more and more prototype manufacturers are joining the industry. Prototyping technology and innovation are changing the world !