How Prototype Companies To Challenge The Industry 4.0?

Regarding industry 4.0, actually it is the digital transformation of manufacturing industries. These developments are fueled by new technology, which provides a more efficient method of organizing and controlling all conventional manufacturing processes.

The term “digital ecosystem” is used to refer to the extra automation and computerization that companies are using to improve their production cycles and “connect” all of the many components of their operations into a unified digital ecosystem. The digital system of industry 4.0 collects data from sources like:

- Strategies for the Industrial IoT;

- Cognitive and artificial intelligence systems;

- Virtual reality

- Robotics tools, including self-driving robots;

The primary distinction between this stage and the previous one is that these digital technologies fuel the physical act of research, production, distribution, and performance in a continuous cycle – the physical-digital-physical (PDP) loop.

Real-time data and insight travel between your prototype manufacturing process’s physical and digital elements through this loop. This link between digital technology and real-world activity is at the heart of Industry 4.0.

The Challenges to Industry 4.0 Adoption in Prototype Manufacturing

It isn’t easy to foster organizational-wide creativity. At the present level of Industry 4.0 development, six out of ten firms acknowledge that implementation obstacles are so high that their industry 4.0 efforts have made little progress over the last year. Among the most often mentioned difficulties are the following:

- A lack of cohesive leadership, which makes cross-unit collaboration within the organization difficult.

- Concerns about data ownership when deciding on third-party vendors to host and operationalize business data

- Short guts to launch a major digitization strategy

- Difficulties in combining data from disparate sources to establish the first connection

- Inadequate knowledge of technologies, suppliers, and IT outsourcing partners can assist with the main project’s execution

While there is no “one-size-fits-all” strategy to implementing an Industry 4.0 program, each business may take various steps to reduce acceptance obstacles. The first step toward becoming an Industry 4.0 company is to accurately assess the return on investment that various digital technologies may produce for your organization.

Top 4 Characteristics of Industry 4.0:

-

Growth of vertical networks

Manufacturers can quickly react to changes caused by changing demand, stock levels, or unanticipated equipment failures using digital-to-physical procedures. Smart factories are highly linked entities, with many systems communicating with one another and adjusting their performance accordingly.

-

Integration the global value chain networks

Physical-digital-physical loops provide more transparency, and businesses can more quickly identify and resolve issues. These enterprise-wide networks may capture data from all activities, from warehousing, marketing and sales, and downstream services. It is possible to review each stage of the procedure at any point in time since it is recorded.

-

Reengineering the value chain

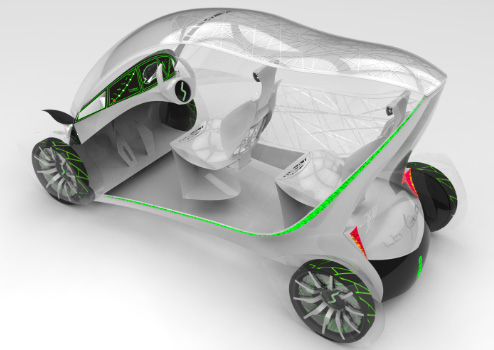

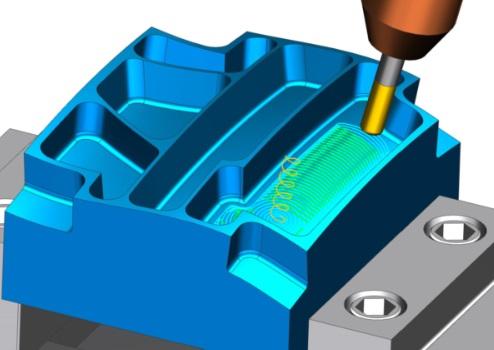

All aspects of product development and prototyping are linked and coordinated with the product life cycle. Between product development and rapid prototyping services systems, new synergies arise.

-

Exactitude through exponential technologies

One of Industry 4.0’s cornerstones is developing an increasingly autonomous and intelligent environment, and it accelerates efficiency further by using machine intelligence, deep learning, sophisticated robotics, and industrial IoT.

Benefits of Industry 4.0 Adoption for Prototyping Companies:

From improved rapid prototype manufacturing efficiency to the deployment of new products and services, the advantages of digitalization are substantial.

Gains in revenue

According to a PwC study, digital goods and services currently generate an extra €110 billion in annual sales in the European sector. In the last three years, pioneering businesses with digital product portfolios have seen above-average growth. Almost half of businesses with industry 4.0 initiatives underway anticipate double-digit growth over the next five years. Additionally, one in five companies anticipates a 20% increase in revenue.

Additionally, businesses may use big data analytics to get a better knowledge of their customers’ requirements. It may utilize the additional information to improve product development and consumer relations.

Efficiency and productivity gains

According to McKinsey, a shift to automated manufacturing 4.0 could boost productivity in technical professions by 45–55 percent. Companies such as Airbus, Cisco, Siemens, and a host of other Industry 4.0 pioneers have already used IoT-assisted new product manufacturing. Businesses may now build more sophisticated IoT ecosystems comprised of devices created by many manufacturers due to the protocol’s ability to allow smooth, quick, and secure cross-platform connection and data exchanges across different IoT systems.

On the rapid manufacturing floor, human-robot partnerships are also forming. New-generation robots can assist prototype companies in automating low-value-added operations and reducing time-to-market. According to MIT, cooperation with robots may save employees’ idle time by up to 85 percent.

A Manufacturing Execution System that automates up to 25% of the client’s activities was developed and implemented with our assistance. Consequently, the customers saw a fivefold increase in productivity and an eightfold increase in application performance.

Machine downtime is reduced

Predictive maintenance in Industry 4.0 entails identifying equipment failures before they occur. Machine learning-enabled systems can identify repeated behaviors that anticipate problems, alert your employees, and schedule inspections. Additionally, these systems adapt with time, becoming capable of detecting even more minute changes and assisting you in constantly optimizing your prototyping manufacturing process.

Additionally, contemporary Industry 4.0 technologies may be customized and optimized for each unique situation. Anomaly Detection Solution continuously improves its algorithm based on input from engineers and real-time data intelligence, thus increasing production efficiency.

Improvements in supply and demand matching

Cloud-based inventory management systems allow more effective supplier relationships. Rather than working in “siloes” environments, you may establish seamless interactions and guarantee that you have:

- High servicing part fill rates;

- A high level of product availability with a low level of risk;

- Increased customer service levels

Integrating your inventory management complicated system with , like SAP S/4HANA, enable Industry 4.0 and data analytics to adapt supply to market demand quickly. Additionally, you may conduct real-time supply chain optimization and get greater insight into potential bottlenecks, thus accelerating business development.

Conclusion

Rapid prototype manufacturing is on the verge of massive digital changes, and early adopters of the invention already see a real return on their investment. To take a step closer to Industry 4.0, consider expanding your understanding of the emerging technologies and use cases that are generating the greatest value – and determining how we may integrate them into our new strategic objectives.

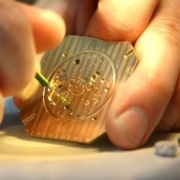

Be that as it may, the CNC Prototype already has a place in the hearts of manufacturers, and also in all customers who only want to see their dream of marketing their products come true, and that they reach the hands of all. When talking about prototypes, we make it clear that it is an initial idea that was materialized, this due to the obvious need that all creators have to observe and evaluate the behavior of a piece, long before it is present in the production lines.

Be that as it may, the CNC Prototype already has a place in the hearts of manufacturers, and also in all customers who only want to see their dream of marketing their products come true, and that they reach the hands of all. When talking about prototypes, we make it clear that it is an initial idea that was materialized, this due to the obvious need that all creators have to observe and evaluate the behavior of a piece, long before it is present in the production lines.

The designer Jessica has made this technique even more advanced, inserting buttons, expertly modeled on the triangles, making the clothes even easier to put on and take off. The result is amazing, as her dress moves adhering perfectly and flowing just like it was made of fabric. Thanks to the 3D scans of the model’s body she managed to get a perfect fit. She worked with a prototype manufacturer to optimize the print quality and aesthetics, thanks to the attention to every detail her garment was recently acquired by the Museum of Modern Art.

The designer Jessica has made this technique even more advanced, inserting buttons, expertly modeled on the triangles, making the clothes even easier to put on and take off. The result is amazing, as her dress moves adhering perfectly and flowing just like it was made of fabric. Thanks to the 3D scans of the model’s body she managed to get a perfect fit. She worked with a prototype manufacturer to optimize the print quality and aesthetics, thanks to the attention to every detail her garment was recently acquired by the Museum of Modern Art. and Under Armor, in the new technological concept, capable of combining 3D printing and shoes. Each of these multinationals has proposed a prototype of a shoe with a plastic sole made entirely with 3D printing techniques, and the future holds many other innovations.The application of rapid prototyping logic to the world of footwear seems to be an ideal solution for the most common problems .The first thing that comes to think of a shoe is the first fundamental advantage: the size. Surely many of us will have found themselves having to make a difficult choice, especially in terms of half sizes and compatibility with foreign measurement systems.

and Under Armor, in the new technological concept, capable of combining 3D printing and shoes. Each of these multinationals has proposed a prototype of a shoe with a plastic sole made entirely with 3D printing techniques, and the future holds many other innovations.The application of rapid prototyping logic to the world of footwear seems to be an ideal solution for the most common problems .The first thing that comes to think of a shoe is the first fundamental advantage: the size. Surely many of us will have found themselves having to make a difficult choice, especially in terms of half sizes and compatibility with foreign measurement systems.