How To Improve the Titanium Machining Technology?

Titanium offers a unique property due to stiffness, outstanding corrosion resistance, toughness, low density, and excellent corrosion resistance. People who have seen a lathe machine or machining center know that cutting titanium sets complex machining demands. Titanium has several properties that make it a popular choice for aerospace and medical tools, but the same features may cause nervous breakdowns for machine operators. Using the right blend of application knowledge and tooling can help you correctly machine even the gnarliest titanium. Today, we will discuss the most important tips to keep in mind whenever you are titanium CNC machining.

So, why is matching titanium a challenge?

Titanium has metallurgical characteristics and properties that make machining more challenging than other metals like cast iron and stainless steel. Titanium is an insulator by nature, the heat during machining stays near the cutting machine, blunting the tool, which creates more heat, and the process continues until the device fails. Another factor that makes titanium difficult for machining is that it is prone to work hardening. As titanium is cut, it becomes hard and even more abrasive to tooling. These are some of the challenges while machining titanium.

What are different types of titanium alloys?

Titanium alloys are known as a mixture of titanium and other elements. These alloys have very high tensile strength and toughness. Titanium is mixed with other parts to provide additional strength, flexibility, and malleability. Titanium alloys are used as various components like turbine blades and bio-materials. Different Titanium alloys come with their own unique set of properties and features.

Here are different types of Titanium alloys:

Pure titanium – Pure titanium is the easiest type of titanium with no alloying elements.

Alpha alloys – Alpha titanium alloys contain aluminum, oxygen, and/or nitrogen.

Beta alloys – Beta titanium alloys contain molybdenum, iron, vanadium, chromium, and manganese.

Mixed alloy – This is the mix of both alpha and beta Titanium alloys.

A glance at the evolution of Titanium Machining:

Around 15 years ago, titanium machining was a challenging and nasty job. Back then, titanium manufacturers were cutting blind and manufacturing parts through trial and error methods. Using hard metal techniques resulted in a costly process, demanded constant monitoring, and produced unpredictable outcomes. Today, end mills have perfect grinds and well-engineered geometries that manufacturers can cut hard materials like titanium without chipping or breaking tools.

Additionally, an adaptive tool from CAM software helps in achieving the steady and productive cutting of material. Another transformation in Titanium CNC machining is additive manufacturing technology, due to which high-torque is no longer required for rough milling, leaving only finishing operations for conventional machines.

Here are some tips for Titanium CNC machining:

Eliminate primary failure modes

Choose a rake cutting tool with a rigid substrate and hard coating to avoid overheating. Also, a small T-land on the device’s cutting edge can help improve the tool’s functioning. However, avoid overdoing it as titanium is challenging and needs a sharp instrument.

Push the heat into the chip

During machining Titanium, the low thermal conductivity traps heat that wreaks havoc on cutting tools. If your machine can handle the additional load, increase the feed rate to push some of the heat into the chip to make the machining tools last longer.

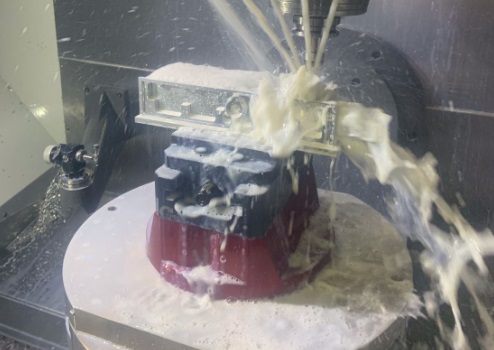

Increase coolant concentration

When cutting titanium, you need to maintain the copious flow of clean cutting fluid. To achieve this, increase the coolant concentration to 10 percent or more. Next, install a high-pressure pump of at least 500 psi to blast chips. Always, always use coolant-fed cutting tools to avoid catastrophic re-cutting of chips.

Choose the right tool

Invest in a high-performance machine tool if you want to achieve success in machining titanium. The high speed of the device can accelerate a chemical reaction between the chip and the tool material. Also, keep in mind that the tool should have good hardness and not react with titanium.

Be strategic

Plan and optimize the titanium machined parts process in advance. Analyze all of the part features, tall and thin walls, and hard-to-machine parts. Choose the right cutters, set the correct feeds and speeds, and generate code that meets the requirement analyzed before.

Titanium machining is not an easy task, but the material properties and usage mean that it is here to stay. As the use of titanium and its alloys continue to grow, more machinists will be dealing with titanium milling in the coming years. All you need to create a perfect blend of heat management, appropriate chip evacuation, correct coating to ensure success in machining titanium parts.