The Benefits of Prototyping And Low Volume Manufacturing In The Aerospace

The aerospace and defense sector was perhaps the first industry to incorporate additive manufacturing into its production process, dating back to 1988 when some leading companies in the sector began to experiment with this new technology. Over the years, additive manufacturing has become more important in the aerospace industry and currently accounts for more than 10% of total industry revenue.

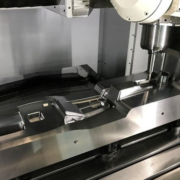

Additive prototype manufacturing (or CNC prototyping) in the aerospace sector is used for both simple elements of the interior of the plane and for complex parts of the engine Additive manufacturing in the aerospace sector is used for both simple elements of the interior of the aircraft and for complex parts of the engine

Aerospace industry

The different current applications of CNC machined prototype in the aerospace sector cover both the manufacture of simple objects, such as armrests, to complex parts and different engine components. Applications such as printing of wings and aircraft parts under microgravity conditions are foreseeable in the near future.

Some of the advantages that CNC prototyping brings to this sector are:

- Reduced time to market: Companies can with CNC prototyping rapidly build prototypes with the required fit, shape and functionality, speeding up design cycles and thereby reducing time to market.

- Complex Design Tools – The ability to 3D print freeform designs aids in the construction of tools or accessories that are difficult or impossible to produce with traditional machining techniques.

CNC prototyping can create cooling channels that adapt to the required curvature.

- Low-cost tooling: Not only does CNC prototyping allow companies to quickly design and test new products, it also helps reduce the cost of manufacturing tooling and accessories.

- Complex part design: CNC prototype enables the design of products with geometries that are difficult to create through traditional prototype manufacturing. Parts can be designed without looking at how they accommodate manufacturing capabilities (which is the case with traditional methods), but instead are designed to offer maximum efficiency. For example, CNC prototyping is already used in aviation to create turbine blades with complex geometric shapes that optimize airflow, which is difficult and time-consuming in traditional prototype manufacturing.

- Simplification of parts: Additive manufacturing or CNC prototyping, allows the manufacture of multiple parts as a single component, thus reducing the assembly effort.

Embedded electronics (embedded): CNC prototype offers the possibility of adding embedded electronics in the part’s own prototype manufacturing, offering a great opportunity for product innovation. In the unmanned aerial vehicle (UAV) industry, this application of CNC prototyping is gaining strong momentum.

Applications of prototyping in the aerospace sector

Some of the direct applications of prototype manufacturing in the aerospace industry:

- Modeling and prototyping.

- Low volume manufacturing of complex aerospace parts.

- Spare parts machining.

- Machined tooling parts.

- Printing of very specific or specialized pieces (for example for space exploration).

- Machining of structures with low weight and high resistance materials.Such as: Titanium

Importance

Currently there is an alternative that the machining industry has found to offer greater reliability in the various products it offers, it is called the manufacture of industrial prototypes. It refers to the ability to test or test a component before it is finally manufactured, assuming a substantial advantage in terms of time and cost savings. In this way, with industrial prototypes, possible weaknesses of the component can be detected before it is put into service. Likewise, the quality of the material is verified and if it can meet the requirements and demands of the service. CNC prototyping is an area of the machining industry that can perfectly provide a solid foundation for product safety.

Technological innovation has made it possible to offer a wide variety of methods using CAD / CAM technology. Assisted prototype manufacturing, for example, stands out for its versatility in guaranteeing a product with all the details that the one who wants to manufacture needs. The responsibilities of the industrial prototype designer lie in knowing the functionality of a number of tools and procedures such as laser sintering. Likewise, the manufacture of industrial CNC prototyping can be done manually or using high-precision machining machine tools. In the same way, the designer must analyze in detail all the aspects through the materials that are delivered by the designers, these may very well be 3D resources, plans or sketches already previously evaluated.