Businesses sometimes can benefit from rapid prototyping in clear materials. However, which production procedures are appropriate for producing transparent or clear parts? For various reasons, product designers may prefer transparent sections that are completely clear, like water, such as LED shells,automotive lighting, all require transparency to work correctly. However, there are occasions when making transparent parts is the only choice.

Other portions have distinct elements that have a role but are not essential to the overall function of the part. Some ink pens, for example, include a transparent glass or plastic that lets the user see how much ink is left inside. This feature isn’t necessary for a pen, yet it’s useful and has a function of “clear” purpose.

In certain circumstances, product designers use transparency or translucency solely for aesthetic purposes to distinguish a product from opaque choices. These goods include consumer electronics shells, pencil sharpeners, cooking utensils, and even application on the kitchen devices.

The Detail Is Key On Transparent Prototype Making

Unlike other types of prototype ,Transparent & Clear Prototype made requests more expertise to the technician’s skill and experience ,require them to be very serious focusing on every detail .Each step must be controlled strictly ,once error happened on a certain area ,probably the whole object will be discarded. Because of the special nature of transparency, you must be careful to prevent scratches, stains, and cracks on the surface of the work piece .Usually there are three types plastic materials making prototype ,Polycarbonate (PC), Acrylic(PMMA)and resins.

How to Make Clear Prototype Parts ?

Whether you require the function or consider of the aesthetic factors on some visual projects, selecting the best rapid prototype services for transparent parts might be tricky. This guide analyses three viable solutions, describing the benefits and drawbacks of each.

1)SLA Rapid Clear Prototyping

Stereolithography is a technique of 3D printing process which is particularly good at producing clear prototypes. This type of rapid manufacturing SLA technique entails directing laser light patterns moving into a thermosetting material to cure it in the shape of CAD model step by step, layer by layer.

The speed of 3D printing transparent parts is a significant advantage, such as for one piece, it can be made succesfully from a CAD design model to a real prototype part within a few hours without any additional technical polishing finish. Clear SLA prototype service is commonly utilized in the dentistry sector to create clear irregular and complicated shape models, and other equipment. Still, we may also use technology to create aesthetically pleasing objects such as jewellery, artwork on display.

2) CNC Machining

One of the most frequent rapid manufacturing services for transparent prototype part is in CNC machining technology. For example, we can use this method to carve durable prototypes from a block of transparent acrylic and translucent polycarbonate using CNC equipment, such as a mill or lathe. For two reasons, acrylic is often preferred clear and original machined material. First, cut off simply, which shortens cutting time and helps machinists attain higher levels of accuracy. Second, with a moderate amount of high polishing to get water-like finish.

Polycarbonate also delivers good results, although it is less machinable and needs more polishing to get good transparency with better flexibility and strength comparing to acrylic. In the meantime, vapour polishing is an essential process, As a result, acrylic is preferred for real optical parts. However, ultimately it depends on what device it’s applied to.

Clear machined parts are often stronger comparing to 3D printed pieces and that can thus be used for various purposes. However, CNC clear plastic prototype is a little bit complicated than other manufacturing processes .Not all prototype companies could offer this type of service, the professional skills and sector knowledge what you have must be remarkable and phenomenal, otherwise ,you cannot get the fabulous quality clear parts .In the meantime ,the engineering team has to be cautious and dedicated on each of manufacturing process steps to enable the successful clear pieces .Transparent prototype is demanding dearly in many industries today .It is significantly important on related application .

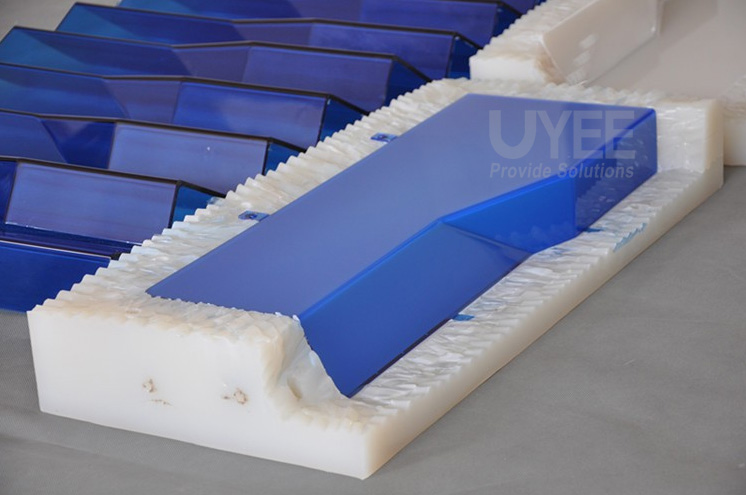

3) Vacuum Casting

For clear or translucent prototyping, probably this process would be a better option than injection moulding for low-budget projects. It employs silicone moulds rather than high cost metal molding, but these soft toolings can manufacture approximately 15 copies of an item, making it suitable for R&D test and validation. However, because the cast elements are somewhat flimsy, they are more suited for decorative applications than practical ones.

Companies frequently use vacuum casting to fabricate clear prototype parts, due to polyurethanes are working well in transparent process and make a good surface finish with little post-processing. In addition, it is very simple to mix the color to the cast components. This approach is commonly used to construct display models, and the shells.

Clear Optical Prototyping Application on Automotive Lighting

We are focusing on automotive lighting prototypes as a full-service offering, which has allowed us to broaden our knowledge and experience in this field. It is now the essential technology and production. Developing methods to create the greatest automotive lighting prototypes in the industry means that we can give the best automotive prototyping services to all of our clients.

Because of our proactive and adaptable work style, we can completely support automotive lighting development initiatives. We can assist at all levels, from mechanical component design assessments and photometric development engineering tests to show vehicle lamp projects.

Craftsmanship in the manufacture of lamp lenses and light guides is an important area that can significantly impact the balance of vision and usability in every component design. We thoroughly understand this sector and cooperate with our clients to meet their fit and finish requirements.

Thanks to our expertise in the automotive prototype market.We can manufacture every kind of outside lens, interior lens, reflector, light pipes, flat guides, and solid guides with continued improving technical abilities and modern equipment, in any difficult form that requires 3, 4, and 5-axis CNC machining .

We also have extensive experience ensuring that the minimal machined tool radius of 0.1mm is used to process the detail for those optical surfaces and areas. As a result, the optical surface tolerance of a machined optical surface can be +/-0.02mm. Then, using our sophisticated polishing technique, we can achieve the best clarity and light transmittance. As a result, the final optical components are super precise, of high optical quality, and devoid of blemishes and scratches.

Specialized In Clear Prototype Machining & High Polishing

UYEE’ s technicians have accumulated rich experience after years of constant exploration. In the process of clear prototype making, before starting production, our engineers will carry out preliminary analysis on CAD model, to some complex prototype which can not be made as a single one ,or considering from the angle of cutting production cost down. It must be split and glued. The key for this technology is how the joint lines to be covered ,enable to not affect the visual experience after completion .At this time, the importance of huge experience is reflected. For example, we will split the object into two or a few pieces in an invisible position or in some rib positions .After polished ,the whole object seems to be a single one ,the joined line is invisible . Of course, we need to communicate and discuss with customers before starting. This method is uniquely suited for creating transparent prototype, quickly, efficiently, and correctly.