What Are Difference between Titanium Machining and Aluminum Machining?

To carry out a machining process, it is necessary to know the physical characteristics of the material to be machined, which are important when selecting tools, cutting angles, speeds, among other parameters. Only in this way can we maximize production efficiency. Obviously aluminum is much harder than titanium. Some important aspects of both aluminum machining and titanium machining are described below.

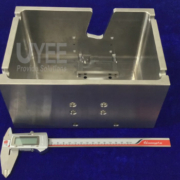

Aluminum CNC Machining

Relatively little energy is required to aluminum machining, since to achieve cutting of the material thanks to its mechanical characteristics, it uses a third of the energy compared to the energy used in the machining of steel. CNC aluminum machining can be achieved with high speeds and removal rates without generating excessive stresses between the material and the cutting tool. High machining speed means higher productivity and better surface finishes.

-

The process tips

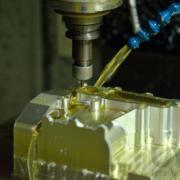

To aluminum machining it is required that the tool have certain special characteristics, it is desirable that the cutting tools used for this type of materials allow the efficient evacuation of the material to avoid dulling that can ruin the part and the cutting tool, as well as the rake angles should be greater than those used to machine steels. Thanks to the high thermal conductivity of aluminum, the cooling process of the cutting tool does not require too much cooling liquid flow, just enough to evacuate loose material.In the market there are a variety of cutting tools with different properties and costs. For the machining processes of aluminum machining, like steel, it is desirable that the tools are very efficient and durable over time.

-

The option of cutting tool

Thanks to technological advances, it is possible to find tools with hard coatings such as DLC (diamond like carbon – carbon like diamond), which provide hardness and tribological properties to the tool, up to complex coating processes such as PVD (vapor deposition) treatments. , with which titanium nitride coatings capable of protecting the tool with superficial layers with titanium are achieved. Some materials for cutting tools for aluminum machining are:

- High speed steels are special high performance steels with high hardness up to 500 ºC and high resistance to wear thanks to alloying elements such as tungsten, molybdenum, vanadium and chromium, capable of forming carbides. Cobalt is added to increase hardness. HSS tools are suitable for machining low-silicon aluminum alloys. Supports the use of large rake angles for better cutting conditions.

- Carbide is a mixture of tungsten carbide and cobalt (CW + Co). This coating provides a longer tool life. They are used in the machining of aluminum with high silicon content and for machining at high cutting speeds.

Titanium CNC Machining

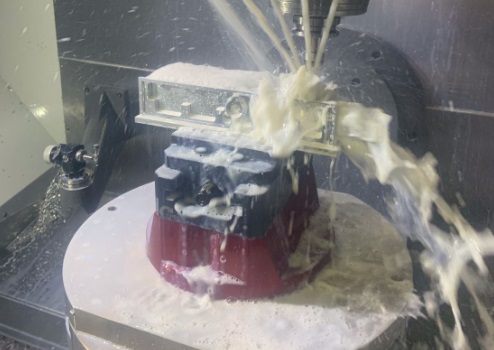

Titanium machining is always a challenge. This is mainly due to the fact that it is an abrasive and cut resistant metal. If we add to this its poor thermal conductivity, machining strategies become a critical aspect when approaching each part to be machined.

-

The process tips

When CNC titanium machining part, you must carefully monitor the amount of material to remove, as well as the advances. A large pass at a high advance will cause great stresses in the machine and an increase in the temperature of the piece. In addition, as a result of the efforts and because it is a ductile material, it is also very possible that deformations appear in the final piece. We must not lose sight of the fact that this ductility can generate vibrations during the machining of the part. Ultimately it is about weighing toughness and cut resistance. The tools used for titanium machining parts are characterized by an important edge. This is to overcome the ductility of the material. Likewise, since it is an abrasive material that accumulates a lot of heat, the tools used to machine titanium have coatings that give them greater durability.

-

The challenge you may meet

Of all the operations in titanium machining, the most complex is threading. External threading can be done using special tools or by using the vortex. On internal threads, especially small diameter threads, chip removal is critical. It must be avoided that it sticks to the edge of the tool, due to the risk of breaking the tap inside the hole to be threaded. The machining of titanium parts is usually demanded in industries such as aerospace, mainly for its weight and resistance.

Above all, you can see that aluminum machining is much easier than titanium machining ,thus ,there is a big difference on cost . In the end, it is necessary to decide which material to use according to the mechanical properties of the product and the design requirements.