What You Need To Know For Metal Casting Technology?

In the industry, some of metal parts fabrication and prototype with CNC machining technology is a good option, especially for low volume manufacturing order, but once product requirements coming into mass production stage ,then, other better process has to be taken into account in order to save money .

Casting machines ensure the die is fully closed. They are classified according to the amount of clamping force they can apply and, in the case of machines, they can range from 550 to 5700 tones. In the cold room process, the metal is first melted in a separate furnace and transferred to a holding furnace; then it is poured into a filling chamber and injected into the mold.

Advantages of the high pressure Die Casting Technology process

High pressure Die Casting Technology can produce very large alloy parts in high volumes and at high speed. The high-pressure process can also produce thin-walled components and cast parts together with different types of parts, such as screws and liners, which are then an integral part of the product itself.

Application

Cold-chamber high-pressure Die Casting Technology is ideal for the production of a diverse range of aluminum and magnesium parts for the automotive industry, such as engine blocks, gearbox crankcases, oil pans, engine mounts and structural parts like cross beams. It is widely used in other industries to manufacture components for applications ranging from the simplest (a lighting component) to the most demanding (parts for an aerospace engine).

Light pressure Die Casting Technology

Although the ability to reduce physical weight has been a key driver of the increased demand for aluminum and other parts in light alloys in recent years, other properties, such as electrical and thermal conductivity, mechanical strength, corrosion, and strength, they also attract the attention of manufacturers in a multitude of industrial sectors.

Due to this unique range of characteristics, light metal can be used to melt complex safety-critical components in the aerospace, automotive and electronics industries. It also represents a cost-effective production option for simple parts, from lighting components to cookware. Three of the most common technologies for producing light alloy Die Casting Technology are: high pressure casting, gravity casting and low pressure casting. Each technology also supports semi-permanent and chill casting processes.

The main advantage of both permanent and semi-permanent Die Casting is its suitability for process automation and large-scale production, making the techniques popular with high-volume fabricators. Depending on the application, alloy part specifications can vary greatly, from geometric complexity and wall thickness to density and strength of the metal.

Sand mold technology process

In sand mold technology, patterns are used to create the molds, preparing and joining these sand molds is a very important step. Patterns or molds are needed to create the empty cavity within the sand and in this way make the desired part.

Two main methods are used for joining the sand molds:

- “Green sand” consists of mixtures of sand

- “Dry sand” is composed of thermally or chemically cured synthetic sand and binders.

Sand Mold consists of pouring molten metal into the mold with the shape of the part or object to be manufactured and waiting for it to harden when it cools. Among the most common foundry metals are cast iron, steel, aluminum alloys and brass.

How does the sand mold work ?

Sand mold is based on the principle of gravity, that is, the only source of energy that forces the metal to fill the mold cavity is the force of gravity. This type of technology is used for pieces in which the quality of finish and dimensional is not decisive. The disadvantages are low dimensional accuracy, poor surface finish, and low strength as a result of slow cooling.

Sand mold will not have as high dimensional accuracy as die casting. In Die Casting, the metal in liquid state is forced into the cavity between the dies by injecting it at high pressure into a die by a special die casting machine, with a closing force of 300 tons. The working pressure is maintained until the metal has completely solidified.

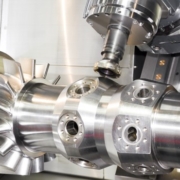

The pieces obtained with this procedure are of high quality in terms of their finish, their dimensions and have great precision. This procedure is one of the most used for the production of large quantities of castings. The mold called matrix, is the most delicate element of die casting, it must be made of steel with great accuracy and cleanliness, which is why precision tools and machines must be used.

Once the matrix is finished, it is subjected to a heat treatment, which increases its hardness and resistance to the attack of liquid metal. In die casting you can control the physical conditions in the solidification of the metal. While the solidification of the metal in a sand mold is carried out under the action of its own weight, leaving pores