Why Custom CNC Machining Parts Are Booming?

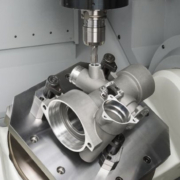

Computer Numerical Control machinery and CNC Machining Parts are booming and growing in popularity with every passing day. This is mainly because the machinery mechanic is a high-tech method that works to remove several barriers preventing the designers from creating the most desired machined parts and products. A significant benefit of CNC machinery is that you can develop some extremely complicated milling and turning parts with higher accuracy that might not be possible using the conventional methods.

CNC machinery to help in manufacturing

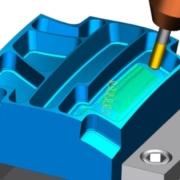

CNC machinery makes use of some special software system to control the act of cutting tools and for handling other instruments of the manufacturing process. For further programming the machine, a skilled programmer uploads the component’s digital model using the basic Computer-Aided Design and document. Further, utilizing the G-Code (CNC coding language), the detailed manufacturing instructions are forwarded to the machine by the programmer, including:

- Where is it required to cut or perform any other tasks for getting machined parts?

- The speed required for performing every action.

- Machinery part that must be coordinated on a priority basis for any task.

- Rate of feeding the raw materials into the workstation or the machine.

- And many more.

This is different from the conventional method of getting machined parts where the entire programming is done in advance, and then the sophisticated machines remotely perform the process. CNC machined parts are also trendy because the process is less time-consuming and is not much labor-intensive. Therefore, it appears as a sleek and elegant solution to get the complex engineering and milled parts.

Factors driving the CNC sector

CNC manufacturing parts production is a standard production method to get the prototypes using the computer programming units. Custom CNC parts and machinery mechanic is booming because of the need for:

- Reducing the operation cost

- Efficiently using the manpower

- Avoiding errors in manufacturing

- Adopting the rise of IoT and predictive analytics.

Rise and development in the industry and spread of automation for production fuels the growth of CNC machinery and reflects the positive trends in the sectors relying hugely on CNC milled parts.

Why custom CNC Machining Parts are booming with increased usage of CNC machining?

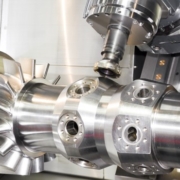

All the CNC machines are beneficial, mainly to design the manufacturing parts with complex angles for manually measuring and cutting. Furthermore, there are certain benefits of using CNC machinery in the present modernized manufacturing industry such as:-

-

Removing Human Error and Disparities

When a person is developing any part or product by own hands or using traditional methods, it isn’t easy to get the same degree of compatibility and correctness as using CNC machinery. CNC machines utilizes designing software, model references in detailed manner, and precision tools to achieve consistency and correctness, thus making CNC machined parts more popular.

These specific things are used to develop and replicate multiple parts that are practically identical (with a common variation of less than 0.020mm—sometimes as tiny as 0.003mm). Even though the excellent traditional machines can’t replicate these results, it implies that you will receive a uniform final product. This is one of the main advantages for aerospace, automotive, dentistry, medical industries, etc. In such industries, uniformity matters a lot. It’s also necessary for some companies developing complex machines or that need several parts to be fitted together correctly.

If any default in size, texture, and shape arises, then the end product might start to malfunction. But with CNC machines and machined parts, it is easy to design products and replicate them over and over – even if the object is incredibly complex and intricate.

-

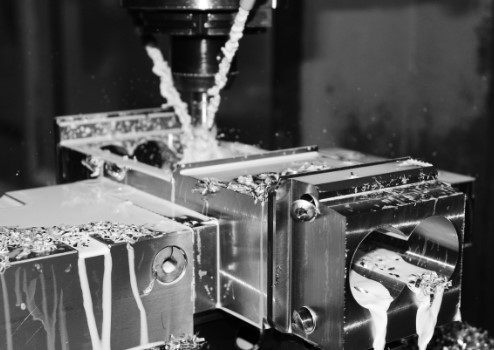

Increase the speed of the Manufacturing Process

Unlike old-fashioned manufacturing of traditional machinery, which demands a designer to provide guidance and oversee the complete process. One of the best things about CNC machinery is a primary hands-off approach.

Several of the CNC machines run automatically and do not require any personal input or direction from experts. The machine will start operating automatically as it gets its guidance from the computer, and the manufacturer provides the raw materials to the machine.

It means that the object will build up faster because no hand-operated labor or excessive downtime is then required. Some of the machines can run 24/7. Thus the CNC machine parts are highly efficient while requiring lesser production time.

-

Using Lesser Resources

One key benefit of using CNC machinery is maximizing the resources at each level of the product construction. In the good olden days, you only required a proficient programmer and engineer to make a digital model or prototype of the design and program the machine.

When it is time to build the product, the CNC machine is very expert and efficient. It can also be programmed precisely to eliminate wastage and only use the required amount of raw material. Thus CNC Machining Parts come with lower waste generation.

-

Decreasing Cost of Manufacturing Over Time

Practicing fewer resources and laborers can also reduce the manufacturing cost. If you are conserving the resources, you can either use later what you have conserved into manufacturing more parts or decrease the final product’s retail cost to earn a competitive lead and attract more buyers.

As you start to outsource your object manufacturing to a full-service CNC machinery provider, you will also save the added costs. The manufacturer responsible for buying software licenses and the machinery, renovating, rebuilding, improving, renewing machines and cutting tools, and letting workers supervise the complete process. You will only pay for the final product or outcome.

-

Increasing the Production

The last advantage of using CNC machinery is that it will offer you more manufacturing choices and you can begin the process with a limited run of high-quality elements. Later on, if the demand for the product is getting higher or required to scale up to the market speedily, it is straightforward to manufacture more components using CNC machinery.You can accurately determine how many parts are required at any instant and eventually helps to decrease excessive inventory. Contact us for high quality custom machining parts now!